2018-07-17

Nide can provide full package of motor stator automatic assembly line for different motor types, like BLDC, pump motor, car motor, induction motor, 3 phase motor ect. This stator production line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine, which are connected by conveyor.

This automatic stator production line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.

The paper inserting part: The production capacity ≤1s/slot (exclude the loading/unloading time). Primary qualification rate ≥99%, after rework, the rate ≥99.9%

The coil winding part: high slot filling rate, small slot opening stator coil winding. Winding mode, such as auto skip, auto cutting and auto indexing could be completed at a time successively, parameter could be set in human-machine interface. Continuous/discontinues winding way and meets the 2 poles. 4 poles, 6 poles coils winding.

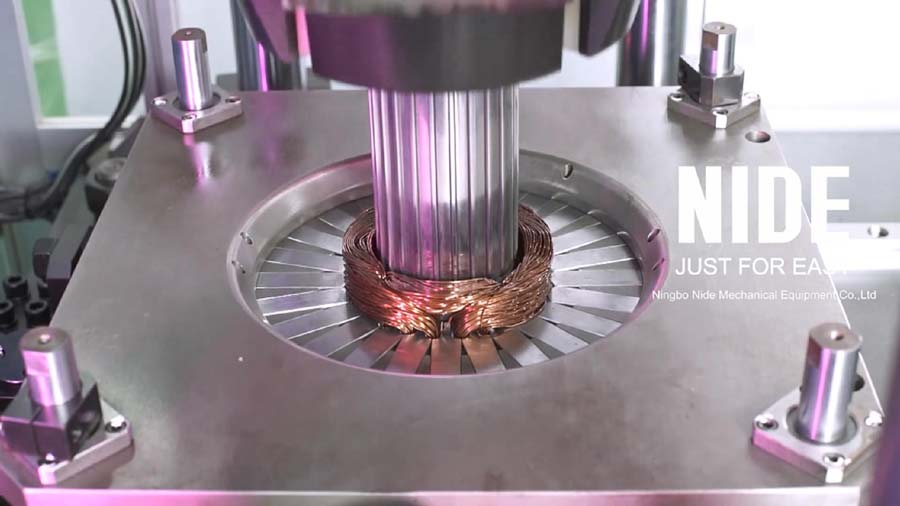

Coil winding inserting machine can insert stator coil and wedge into the stator slot automatically. It reduces the labor and improve the efficiency and accuracy.This machine is suitable for Polyester Film wedge roll material with fixed thickness and fixed width (width and thickness dimension is provided by customer). For the wire, both copper wire and alum wire are OK.

The lacing machine is controlled by PLC. Different lacing mode could be set such as slot lacing, interval lacing, and fancy lacing. Tooling change is fast and convenient. There are single lacing machine, doulble station lacing machine and horizontal lacing machine.

The forming machine is used to do coil forming. Before lacing, the stator coil should do one time forming as it can be better to do lacing. After lacing, the stator coil should do final forming. Production capacity ≤14s/set (exclude loading/unloading time)

After all the above step, the stator production process is finished. Now it needs to do testing to check if it is qualified. The testing machine can test resistance, hi-pot, insulation resistance ect.