PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd is a leading bearing manufacturing and trading company committed to providing high-quality and reliable bearing products and excellent services to global customers. Product scope: We offer magnet,insulation paper,thermal protector,motor cover and lamination,shaft,commutator,fan, etc. We also offer customized bearing solutions to meet specific customer requirements and applications. Quality control: We attach great importance to product quality, adhere to international standards and strict quality control processes. Our production facilities are equipped with the most advanced equipment and technology, and our bearings undergo strict testing and inspection to ensure they meet the highest quality standards.

We have obtained ISO9001 certification to ensure consistent quality throughout the entire product line. We strive to ship on time and flexibly process orders to ensure a seamless experience for our esteemed customers. As an international trading company, we cater to global customers. Our products are exported to various countries and regions, and we have established strong partnerships with reliable international logistics companies.

| Parameter | Information |

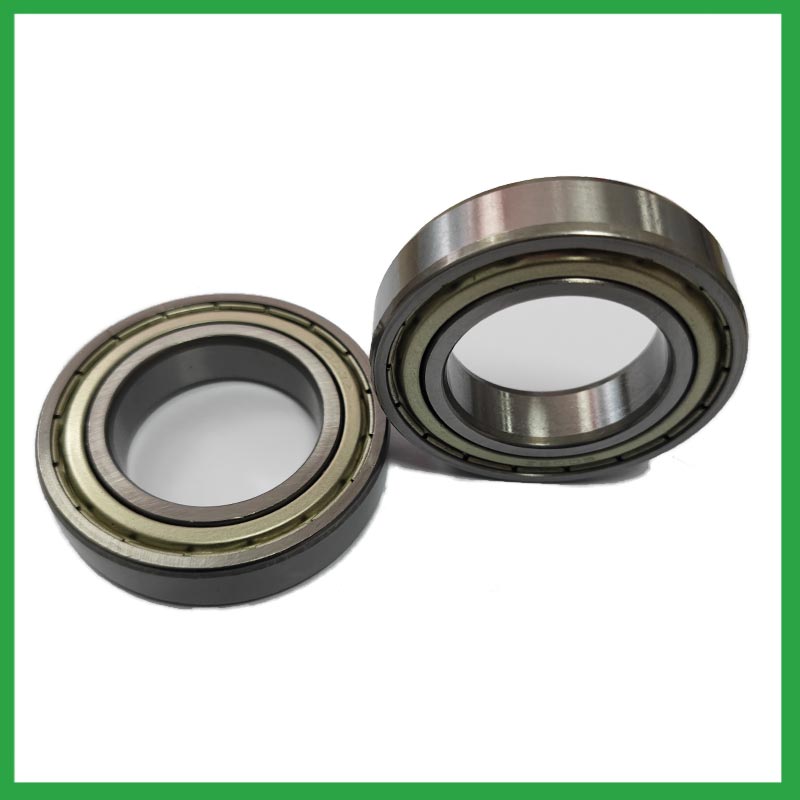

| Product Name | ball bearing physics |

| Brand Name | Nide |

| Place of Origin | Ningbo,Zhejiang |

| Type | Ball |

| Material | stainless steel, etc. |

| Sample | Avaible |

| Warranty | 3months-1year |

| Lubrication | Dry/ Oil |

| Application | textile machinery, etc. |

| Port | Ningbo/Shanghai |

| Size(mm) | customize |

| Export Country | Argentina,Brazil,South Korea,Benin,Serbia and Montenegro,Anguilla,Montserrat...etc |

| Export region | Asia,Oceania,Africa... |

| Certification | ISO 9001 Certification,CE-stator coil lacing machine,CE-stator coil winding machine,etc |

| Precision Rating | as per customer's requirement |

| Feature | High speed,Good wear resistance...etc |

| Packaging Details | Suitable for sea transportation |

| Color | Silver gray+customized |

| Seals Type | Rubber seals |

| Service | Prompt Delivery |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

Bearings with ball bearings as rolling elements mainly include adjustable ball bearings,angular contact ball bearings,self-aligning ball bearings,thrust ball bearings, etc.

During the disassembly process, the outer shell should be kept intact to avoid unnecessary damage;

When replacing installation components, attention should be paid to the accuracy of the support components to prevent deformation;

During the disassembly process, attention should be paid to protecting the surface quality of the ball bearing to ensure its performance;

During the operation, attention should be paid to removing surface dust to ensure the quality of the ball bearing.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball bearing physics---FAQs Guide

2.Are there specific ball bearing physics designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

3.What is the role of ball bearing physics in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

4.Can ball bearing physics operate in high-speed applications, and what design features make them suitable for such conditions?

5.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

6.As a ball bearing physics manufacturer,What is your payment method?

7.How do ball bearing physics provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

8.What are the advancements and innovations in ball bearing physics technology that have emerged in recent years?

9.How do manufacturers ensure the quality and reliability of ball bearing physics through material selection and precision machining?

10.Can ball bearing physics be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

1.About ball bearing physics,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

2.Are there specific ball bearing physics designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control ball bearing physics are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses.

Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

3.What is the role of ball bearing physics in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

When a load is applied to a ball bearing, the ball bearing physics roll freely between the inner and outer rings. This rolling action significantly reduces friction compared to sliding contact, resulting in smoother rotation and reduced wear.

4.Can ball bearing physics operate in high-speed applications, and what design features make them suitable for such conditions?

They have very low rolling friction and are optimized for low noise and low vibration. This makes them ideal for high-speed applications. ball bearing physics are comparatively easy to install and require minimal maintenance.

5.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a ball bearing physics manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

6.As a ball bearing physics manufacturer,What is your payment method?

We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.

7.How do ball bearing physics provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, ball bearing physics operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

8.What are the advancements and innovations in ball bearing physics technology that have emerged in recent years?

Significant advancements have been made in ball bearing physics steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

9.How do manufacturers ensure the quality and reliability of ball bearing physics through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

10.Can ball bearing physics be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.