PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Model:NDPJ-HXQ-202

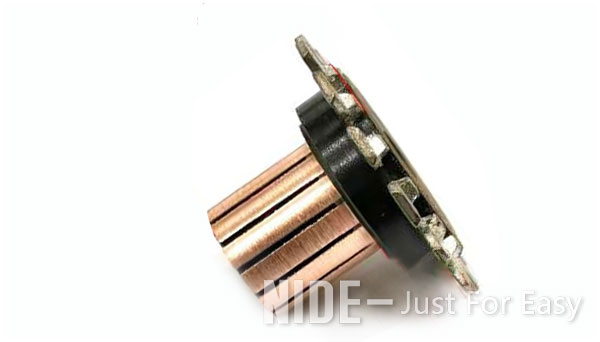

This commutator is suitable for hollow cup motors,Coreless motor.

Categoryes: Commutator

Electrical hollow cup motor copper segmented commutator

This commutator is suitable for hollow cup motors. The advantage is that it does not affect the performance of the motor, but also can guarantee the process of the motor in the production process, and the commutator processing is more stable, and the design and processing of the mold can be more convenient and quick, which saves costs and improves the process.

At present, the commutator of the hollow cup motor is basically spot welding or tin welding to complete the rotor welding process, but in this process, the commutator metal pole pieces often appear due to the unstable pressure of the spot welding machine and the current Inconsistency or dimensional tolerances of the commutator lead to undesirable conditions such as deformation and opening. Some or the inconsistency of the temperature of the electric winding iron and the quality of the solder wire during the soldering process causes the commutator body to be burned and deformed; and the existing The combination of the motor shaft and the plastic body and the combination of the pole piece and the plastic body are not ideal.

Commutator design scheme

Our commutator adopts a new design scheme. The technical problem to be solved is to provide a commutator for coreless motors that will not deform the metal pole piece, open the mouth and burn the plastic body during the welding process, and can increase the strength of the combination. .

Our commutator for coreless motors includes a plastic body, pole piece and motor shaft; the plastic body is provided with a thimble hole; the head of the pole piece is flush with the concave surface of the body head to wrap the upper end surface of the main body, the motor shaft and the plastic The body is connected. The thimble hole of the commutator is a cone with a small top and a big bottom; the pole piece bears the downward pressure during welding, so that the pole piece will not sink and deform.

A trapezoidal slot is provided at the junction of the commutator motor shaft and the plastic body. The plastic of the main body and the shaft are integrated to increase the holding force of the motor shaft to ensure that the motor shaft and the main body are not separated, and the precision of the mold is used to ensure the coaxiality.

The lower end surface of the commutator pole piece of the hollow cup motor is higher than the main plane of the plastic body. It is used to increase the contact area during welding and buffer the pressure during spot welding to make the welding more reliable.

Commutator features

The head of the pole piece of the commutator adopts the method that the body is a flat head and wraps the end face of the pole piece to increase the strength of the combination of the pole piece and the body. The wrapping method is used to ensure that the pressure and temperature during welding do not deform the pole piece, and the injection mold is used The design of the pole piece improves the installation position of the pole piece, that is, the main plane of the pole piece is higher than the body plane, and the circular dot pattern is densely distributed on the main plane of the pole piece to increase the contact area during welding and to buffer the pressure during spot welding. , To make the welding more reliable, the pole piece thimble hole on the plastic body adopts a small top and a large taper, so that the pole piece will withstand the downward pressure during welding, so that the pole piece will not sink and deform; on the motor shaft and The head of the plastic body is connected with a trapezoidal notch to integrate the body plastic and the shaft body, increase the holding force of the motor shaft, ensure that the motor shaft and the body are not separated, and use the precision of the mold to ensure the coaxiality.

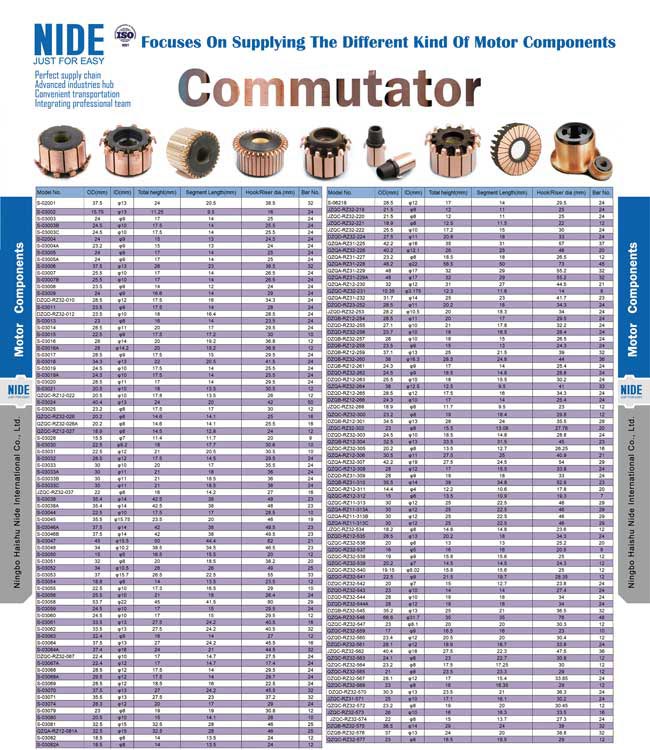

Commutator parameters

| Product name: | 13P segment coreless motor commutator |

| Brand: | NIDE |

| Material: | silver copper reinforcement |

| Scope of application: | Electric tools, medical equipment, beauty instruments, aviation, aerospace, model airplanes, portable instruments, etc. |

| Size: | customized |

Commutator picture

Information needed for commutator inquiry:

It will be better if customer could send us detailed drawing including below information.

1. Commutator dimension: OD, ID, total height, and copper height, bar number.

2. Commutator type: hook type, raiser type or planner

3. Copper material: Agcu/ Cu

4. Commutator applications

5. Required quantity

6. Copper bush needed or not

7. Other technical requirement.

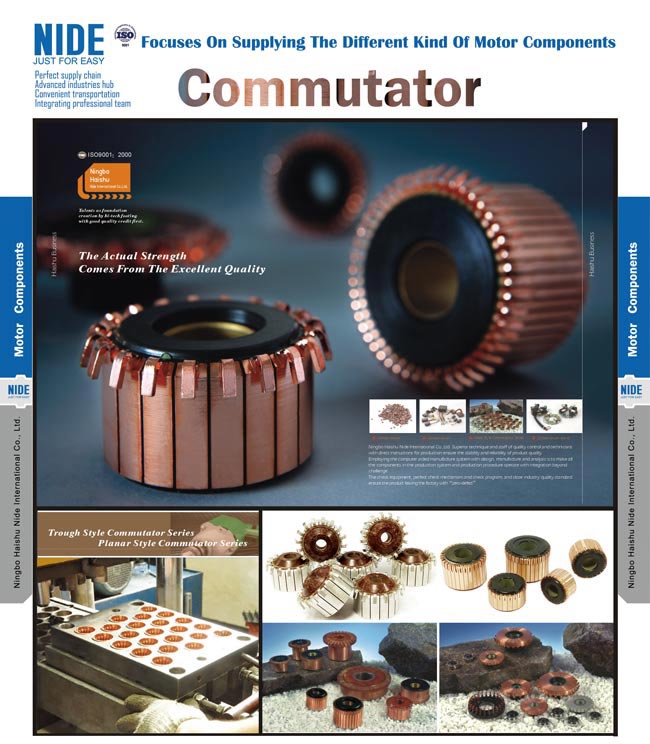

Nide produces more than 1200 different types of motor commutator, including hook type, riser type, shell type, planar type, ranging from OD 4mm to OD 150mm and we are professional in manufacturing commutator for many years. The commutators are widely applied to automotive industry, power tools, household appliances, and other motors.If our existing models are not suitable for you, we could also develop new tooling according to your drawing and samples.

Besides, we can supply the full range of motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper material, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com