PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Model:NDPJ-HXQ-203

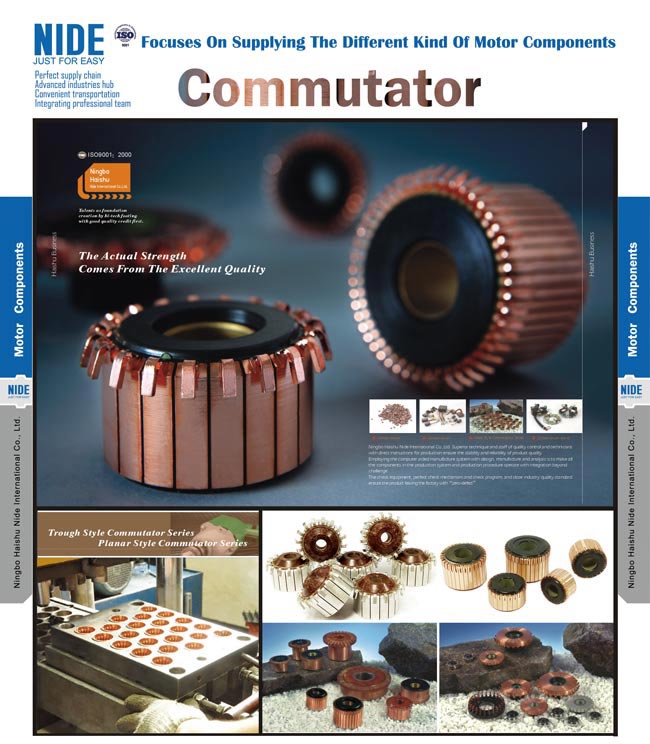

The Hook Commutator products are mainly used for fuel vehicles, new energy vehicles, automobile generators, gasoline generators and other fields.

Categoryes: Commutator

Window lift motor commutator auto electronic accessories

The Hook Commutator products are mainly used in low-power motors and micro-special motors, and are used in fuel vehicles, new energy vehicles, automobile generators, gasoline generators and other fields. The commutator plays a role of rectification, and its role is to make the direction of the current in the armature winding alternate to ensure that the direction of the electromagnetic torque remains unchanged.

The number of micro-motors used in automobiles is related to the grade of automobiles. For example, low-end and medium-end models use at least 20-30 motor commutators, while mid- and high-end models need to use 60-70 or even hundreds of motor commutators. Device. There are more and more applications of commutators in automobile production.

The motor commutators are mainly used in window lifts, wipers, sunroofs, automatic trunk opening and closing, seat adjustment, rearview mirror adjustment, ABS, EPS and other scenes.

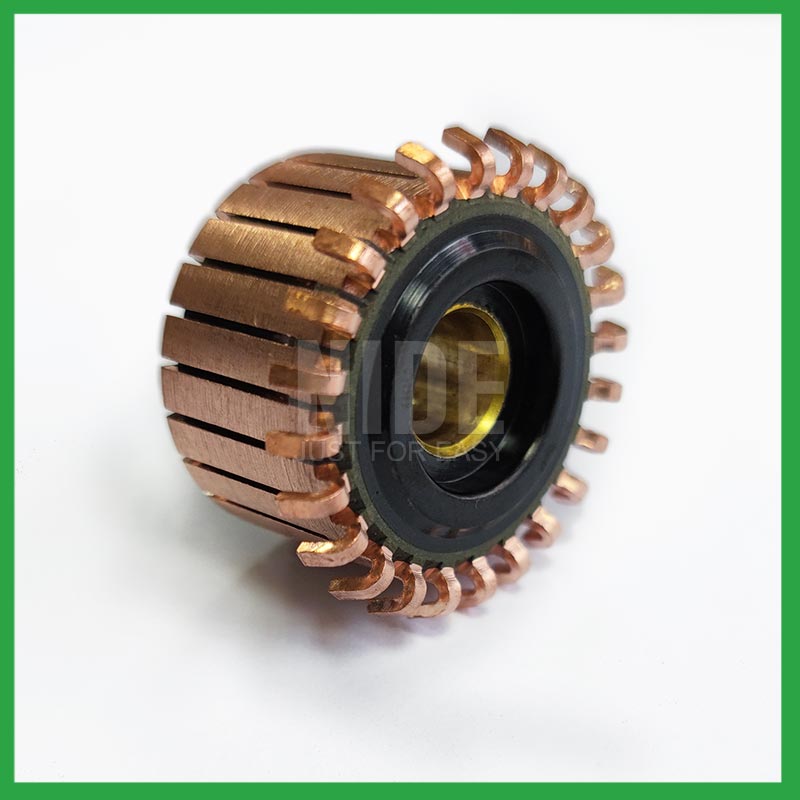

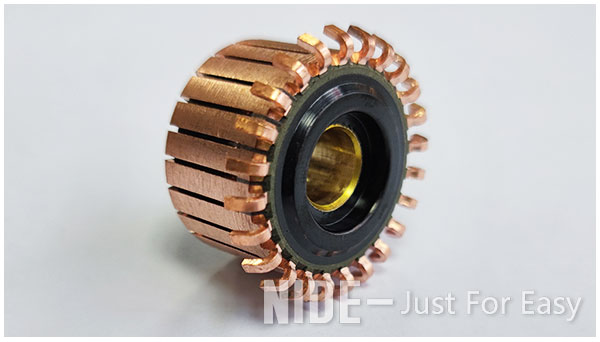

Hook Commutator Details

| Product Name : | Auto Electronic Commutator Accessories |

| Color: | Copper Tone |

| Material: | Copper, Steel |

| Size: | customized |

| Gear Tooth Quantity: | 24 Pcs Or customized |

| MOQ: | 5000 pcs |

| Delivery: | 20-50working days |

Hook Commutator Picture

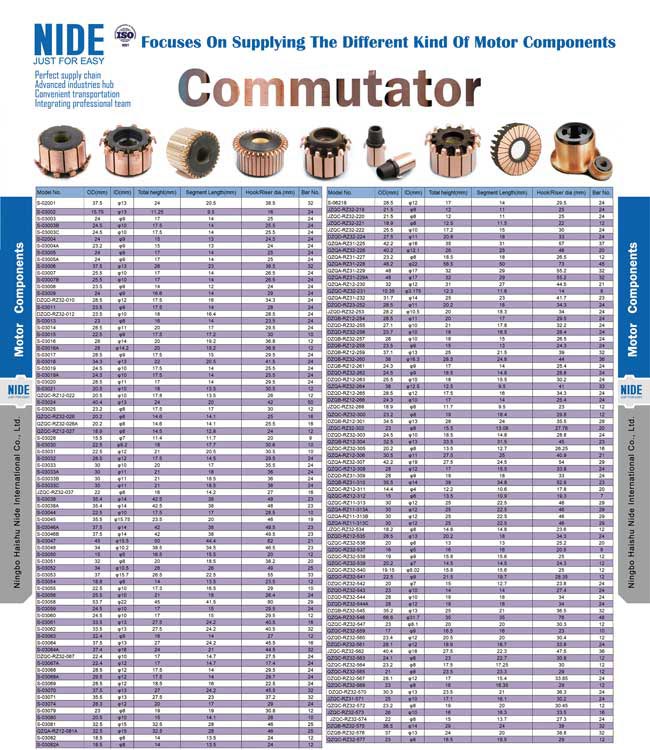

Information needed for commutator inquiry:

It will be better if customer could send us detailed drawing including below information.

1. Commutator dimension: OD, ID, total height, and copper height, bar number.

2. Commutator type: hook type, raiser type or planner

3. Copper material: Agcu/ Cu

4. Commutator applications

5. Required quantity

6. Copper bush needed or not

7. Other technical requirement.

Nide produces more than 1200 different types of motor commutator, including hook type, riser type, shell type, planar type, ranging from OD 4mm to OD 150mm and we are professional in manufacturing commutator for many years. The commutators are widely applied to automotive industry, power tools, household appliances, and other motors.If our existing models are not suitable for you, we could also develop new tooling according to your drawing and samples.

Besides, we can supply the full range of motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper material, shaft, magnet, fan, motor cover,etc.

Tags: commutator manufacturer

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com

How do commutator manufacturers ensure the performance and reliability of their products in various motor and generator applications?

Nide International Co., Ltd. suggests that the following key practices and quality control measures can be taken to ensure the performance and reliability of its products in various motor and generator applications.

1. Material selection: The manufacturer selects materials with high conductivity, wear resistance, and corrosion resistance for the commutator blade. Choosing appropriate materials is crucial for ensuring long-term performance and reliability.

2. Precision manufacturing: The commutator is manufactured with high precision to meet strict tolerance requirements. This precision includes both mechanical and precision machining processes to ensure that the sector segments are perfectly circular, planar, and concentric.

3. Quality inspection: Nide International adopts strict quality control and inspection processes at all stages of manufacturing to detect defects, ensure consistency, and verify whether the commutator meets the required specifications.

4. Balance: In order to prevent vibration and extend the lifespan of the motor or generator, the commutator is balanced to a high tolerance. This can minimize brush wear and prolong the service life of the entire system.

5. Surface finish: A smooth surface finish is crucial for reducing brush wear and ensuring optimal electrical contact. Nide International closely monitors the smoothness of the commutator blades.

6. Brush Compatibility: Ensure that its commutator is compatible with specific types of brushes. The correct pairing of brushes and commutators is crucial for optimal performance.

7. R&D: Continuous R&D work helps Nide International stay at the forefront of commutator technology. We continuously strive to improve materials, design, and manufacturing processes.

8. Customization: We offer customization options that allow customers to specify unique requirements to adapt the commutator to professional or demanding applications.

9. Compliance with Standards: Nide International adheres to industry and international standards to ensure that its products meet the safety and performance requirements of various applications.

Does the commutator manufacturer provide customized design options to meet special technical requirements or specific electric equipment?

Yes, many commutator manufacturers(Nide International Co., Ltd)offer customized design options to meet special technical requirements and cater to specific electric equipment needs.

These customization services allow customers to tailor the commutators for unique applications, taking into account factors such as voltage, current, dimensions, and operating conditions.

This ensures that the commutators are optimized for specific requirements and seamlessly integrate into the customer's electrical equipment, contributing to enhanced performance and reliability.