PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Model: NDPJ-RBHQ-63

The thermal protector is suitable for various motors, electrical tools, chargers, transformers battery, fluorescent ballasts and lightings, electric pad, electric blanket, laminatorand Home appliances, etc.

KW bimetal thermal protector temperature and current thermal protector

The KW bimetal thermal protector has sealed case, which would protect the parts inside from damaging or polluting.

When ambient temperature increase to the prescribed value, the bimetal inside the thermal protector would sense the heat and trip the circuit off. When temperature is decreased down, it would reset again.

Thermal Protector Application

The thermal protector is suitable for various motors, electrical tools, chargers, transformers battery, fluorescent ballasts and lightings, electric pad, electric blanket, laminatorand Home appliances, etc.

Thermal protector Special Features

1、Precise operation of the operating temperature and the creep phenomenon does not ocuur;

2、High temperature resistant lead wire, customizable as per customer requirements

3、Miniature size, easy to install

4、Trip off Temperatures: 55-160 degrees centigrade. Special specifications are available for customization.

5、Optional Normally Close type and Normally Open type

6、Repeatable temperature performance over life

7、Each part enbironmental standards are strictly enforced.

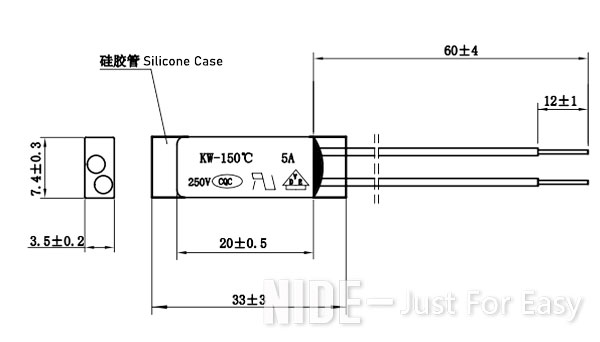

Thermal protector technical requirements:

| The lead wire | UL3135, 20AWG red silicone wire. (customized) |

| Contact capacity: | 50V 5A, contact type: normally closed. |

| Contact resistance: | When the contact is closed, the resistance between the lead wires is ≤50MΩ. |

| Rated breaking temperature: | 150±5°C; Rated reset temperature 105±15°C. |

| Mechanical strength of lead wires or terminals: | should withstand static tension of 60N/ 1min without loosening, cracking, deformation and other defects |

| The insulation resistance of the lead wire or terminal and the surface of the insulating layer of the casing | ≥10MΩ. |

| Electric strength: |

a. When the contact is normally closed, the lead wire and the insulating layer of the casing should withstand 1500V/1min without flashover and breakdown. b. When the contacts are thermally disconnected, the lead wires should withstand 500V/1min without flashover and breakdown. |

Thermal protector Picture Show

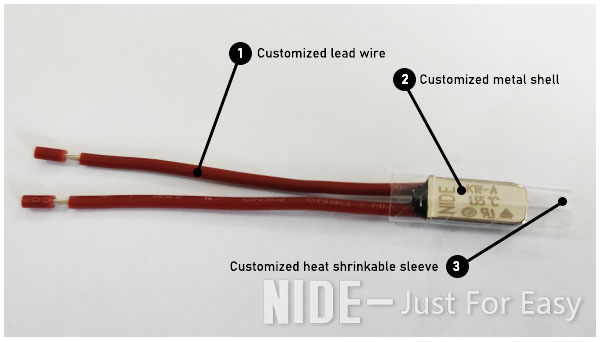

Customized Thermal Protector Structure:

1. Customized lead wire: Customized wire material, length and color according to customer needs

2. Customized metal shell: Customize different material shells according to customer needs, including plastic shells, iron shells, stainless steel shells, and other metal shells.

3. Customized heat shrinkable sleeve: Customize different high temperature resistant polyester heat shrinkable sleeves according to customer needs

About Motor component and accessories

NIDE can supply the full range of electric motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com