PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

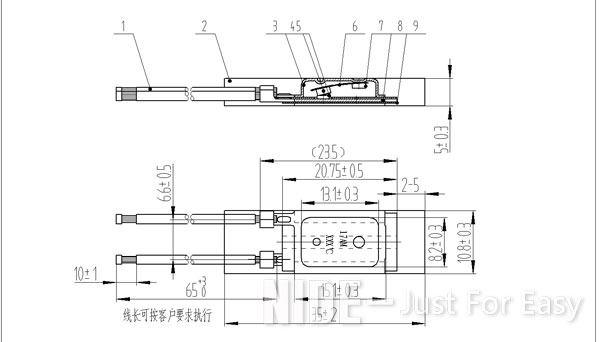

Model:NDPJ-RBHQ-64

17AM temperature current thermal protector is used in washing machines, dishwashers, dryers, vacuum cleaners and various horse and DC motors for industrial applications with operating voltages of 120VAC and 240VAC.

17AM temperature current thermal protector for drum washing machine

This 17AM series thermal protector switch is equipped with terminals, especially suitable for front-loading washing machine motor accessories.

17AM series self-resetting over-temperature and over-current protection thermal switch (thermal protector) is a product with dual sensing characteristics of temperature and current. The product has the characteristics of advanced structure, sensitive action, large contact capacity and long life. Used in washing machines, dishwashers, dryers, vacuum cleaners and various horse and DC motors for industrial applications with operating voltages of 120VAC and 240VAC.

17AM Thermal Protector Performance

| Product name: | 17AM temperature current thermal protector for drum washing machine |

| Rated Current: | 16A/125VAC、8A/250VAC |

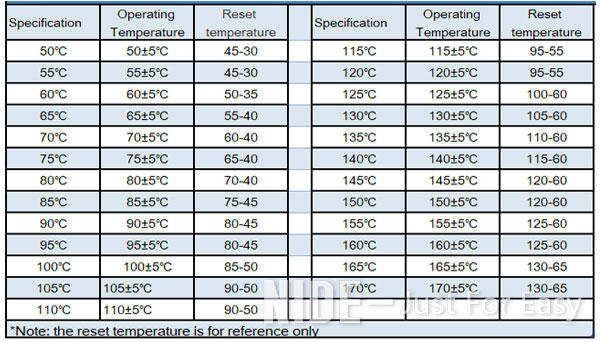

| Operating Temperature, | 50~170℃,Tolerance±5℃(details as per attached list). |

| Tensile Test: | The wiring terminal of the product shall be able to withstand a tensile force greater than or equal to 50N. The riveted joint shall not be loose and the wire shall not break or slide out. |

| Insulation Voltage: |

a. The thermal protector should be able to withstand AC880V between the wiring after thermal breakdown, lasting for 1min without breakdown flashover phenomenon; b.AC2000V can be withstood between the terminal lead of the thermal protector and the insulating shell, lasting for 1min without breakdown flashover phenomenon; |

| Insulation Resistance: | Under normal conditions, the insulation resistance between conductor and insulation shell over 100 m Ω.(the meter used is DC500V insulation resistance meter). |

| Contact Resistance: | The contact resistance of thermal protector should be not more than 50 m Ω(do not contain lead). |

| Air Tight Test: | Protector in greater than 85℃ water(water is not boiling),it should be no continuous bubbling. |

| Heating Test: | The product place 96 hours at 150 ℃ environment. |

| Wet Resistance Test: | The product in the environment of the 40 ℃, relative humidity 95% for 48 hours. |

| Therma Shock Ttest: | Products in 150℃, 20℃ environment alternating place every 30 min, a total of five cycles. |

| Vibration Resistance Test: | The product can withstand the amplitude of 1.5mm, frequency change of 10 ~ 55Hz, scanning change period of 3 ~ 5min, vibration direction X,Y, Z,it vibrates continuously in each direction for 2 hours. |

| Drop Test: | The product dropped freely once from the height of 0.7m. |

17AM Thermal Protector Picture Show

17AM series of thermal protector operating temperature comparison table

About Motor component and accessories

NIDE can supply the full range of electric motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com