PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Model:NDPJ-CW-78

These Magnets is very durable will not Break in Normal Use since the Magnets are Protected inside the Steel Cups which Greatly Increase the Longevity of the Magnets.

Categoryes: Magnet

Rare Earth Neodymium Round Base Cup Magnet With Heavy Duty Countersunk Hole

The Rare Earth Neodymium Magnet is made of Strong Neodymium Magnet, Unbelievable Holding Power for the Size, Up to 100 Pound Holding Power per Magnet.

These Magnets is very durable will not Break in Normal Use since the Magnets are Protected inside the Steel Cups which Greatly Increase the Longevity of the Magnets.

These round base rare earth magnets with heavy duty countersunk hole and six free screws. They can be used in various life scenes and industrial equipment. Using the screws to install the magnet on the surface of the object or use the magnet to fix it on the surface of the metal object. The neodymium magnet heavy duty surface is smooth and rust-proof. The magnets with holes are removed without leaving any stains.

Applications:

1. Electrical field: generators, motors, servo motors, micro-motors, motors, VCM, CD / DVD-ROM, vibration motors.

2. Electronics: permanent magnetic actuator vacuum circuit breakers, meter, sound meter, a reed switch, magnetic relays, sensors .

3. Machinery and equipment: magnetic separation, magnetic crane, magnetic machinery.

4. Acoustic field: the speaker, receiver, microphone, alarm, stage audio, car audio etc.

5. Healthcare: MRI scanners, medical equipment, magnetic health products etc.

6. Daily life: strong refrigerator magnets, for arts and crafts, DIY projects, hanging spice jars, pictures, whiteboards, tools in the garage, or science classroom at school, etc.

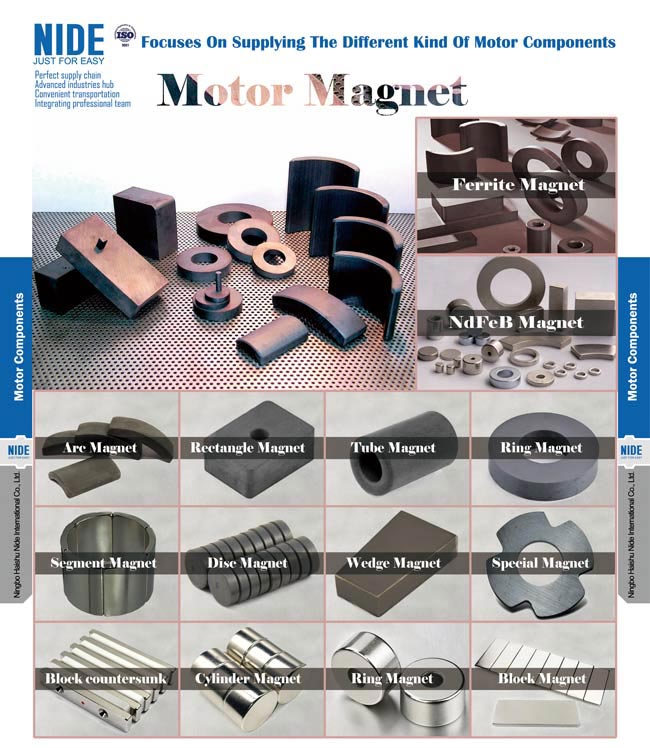

We can offer a variety of NdFeB Magnet and Ferrite Magnet, If you need special magnetic tiles, we can also customize according to your needs.

About Motor component and accessories

NIDE can supply the full range of electric motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

Tags: Other Magnets

How long is the service life of Magnet products and how can they be maintained to extend their service life?

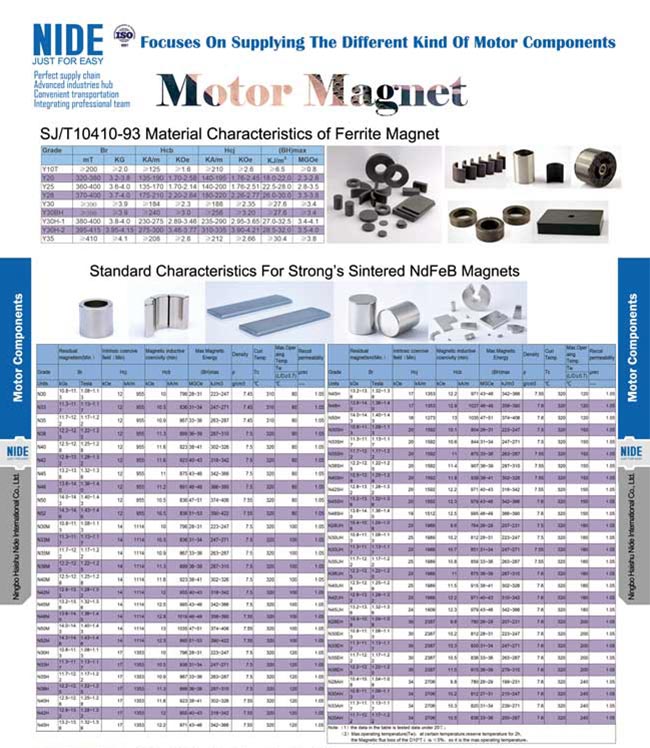

The service life of magnet products varies greatly due to factors such as magnet type, quality, operating conditions, and usage. Permanent magnets include neodymium, samarium cobalt, and ferrite magnets, known for their long-lasting magnetism. Under optimal conditions, their service life ranges from a few years to several decades, or even longer.

Regarding how to maintain and extend the service life of magnet products, Ningbo Haishu Nide International Co., Ltd has these suggestions:

Avoid overheating: High temperatures can cause permanent magnets to demagnetize. Keep the magnet away from heat sources and avoid temperatures above the Curie temperature (i.e., the temperature at which the magnet loses its magnetism).

Prevention of mechanical damage: Avoid physical impacts, impacts, and mechanical stresses that may cause the magnet to rupture or shatter. Handle with care.

Corrosion prevention: Some magnets, such as neodymium magnets, are susceptible to corrosion. To protect them, use appropriate coatings such as nickel or epoxy resin to protect the magnets from moisture and corrosion.

Proper storage: Store the magnet in a clean, dry, and temperature controlled environment. Avoid stacking or storing them together with other materials that may demagnetize or damage the magnet.

Stay away from electric fields: Strong electric fields can affect the magnetism of certain magnets. Keep the magnet away from high-voltage equipment.

Avoid demagnetization: Avoid placing the magnet in the opposite magnetic field that can demagnetize it. For example, this situation occurs when neodymium magnets are exposed to a strong external magnetic field.

Regular inspection: Regularly inspect the magnet for any signs of damage or weakening of magnetic field strength. Replace or re magnetize the magnet as needed.

Correct handling: When using a powerful magnet, be careful to prevent injury, squeezing, or accidents caused by its strong attraction.

Remagnetization: In some cases, when the strength of a magnet weakens over time, it can be remagnetized to restore its original characteristics. This should be done by professionals using necessary equipment.

If you don't understand anything, you can consult us at Ningbo Haishu Nide International Co., Ltd.

What types and size specifications are available for Magnet products to choose from?

Magnet products come in various types, including neodymium, ferrite, and samarium-cobalt magnets, each with distinct properties, and they are available in a wide range of size specifications, from small, coin-sized magnets to larger, custom-designed magnets, providing flexibility to choose the most suitable magnet for specific applications.

How to choose suitable products based on different uses?

Choosing suitable magnet products based on different uses depends on several factors:

Type of Magnet: Select the appropriate type of magnet, such as neodymium, ferrite, or samarium-cobalt, based on the required magnetic strength, temperature resistance, and other magnetic properties for your specific application.

Size and Shape: Consider the size and shape of the magnet, ensuring it fits within the available space and aligns with the design requirements of your application.

Strength: Determine the required magnetic strength for your application. Neodymium magnets, for example, are known for their high strength, while ferrite magnets are less powerful.

Temperature Range: Assess the operating temperature range of the magnet and choose one that can withstand the temperature conditions in your application.

Coating and Protection: Consider whether the magnet needs a protective coating, such as nickel or epoxy, to shield it from corrosion or damage in the intended environment.

Environmental Factors: Evaluate the environmental conditions, such as exposure to moisture, chemicals, or strong electromagnetic fields, and select a magnet that can withstand these factors.

Application Specifics: Take into account the specific requirements of your application, whether it's in a motor, sensor, medical device, or any other context, and choose a magnet that aligns with those needs.

Customization: If standard sizes and types don't meet your requirements, consider custom-designed magnets that can be tailored to your application.

Safety Considerations: Be mindful of safety concerns, especially if the magnet will be used in a consumer product, and choose a magnet that poses no harm to users.