In recent years, the world has vigorously developed new energy sources. In addition to solar energy and nuclear energy, the development of wind energy has gradually shown its unique advantages. This provides new opportunities for the development and innovation of our electric carbon industry: lightning protection grounding carbon brushes, slip ring carbon brushes, carbon brushes for signal transmission, etc. The benign and rapid development of my country's automobile industry, the rapid growth of power tools, household motors, and toy model industries, and the surge in demand for related products abroad have also brought new opportunities for the development and improvement of my country's electric carbon.

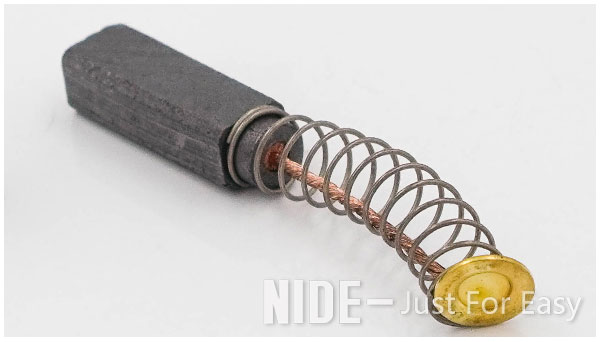

The motor is divided into DC motor and AC motor. Because of the rolling of the rotor, the DC motor needs to continuously switch the direction of the current according to the position change of the coil in the constant magnetic field, so the coil of the DC motor needs a commutator. Carbon brushes are an important part of the commutator and are a type of brushes. Because of the rolling of the rotor, the brushes always rub against the commutation ring, and spark erosion will occur at the moment of commutation. The brush is a wearing part in the DC motor. Its function is to rotate the motor, input the electric energy to the coil through the commutator, and change the direction of the current.

According to different materials, carbon brushes can be divided into metal graphite carbon brushes, natural graphite carbon brushes, electrochemical graphite carbon brushes, etc. Among them, metal graphite is mainly used for high-load low-voltage motors, and natural graphite is used for small and medium-sized DC motors and high-speed turbine power generation. Electrochemical graphite is widely used in various types of AC and DC motors.

Carbon brushes belong to the traditional motor commutation method. The advantages are simple structure, no need for driving, and low cost. They are mostly used in various small-scale motors and household electric equipment, while brushless motors have long service life, no frequent maintenance, and low noise. The disadvantages are mainly due to the high cost due to the need for additional drives. At present, it is mainly used in precision instruments and other equipment that strictly control the motor speed and reach a high speed.

In addition to being used in generators, carbon brushes can also be used in various AC and DC motors, such as car starters, brushed motors for electric vehicles, hand drills, grinders, alternator turbines, micro motors, power tools, electric Locomotives, carbon skateboards, machinery, etc.