2023-11-22

Ningbo Haishunide International Co., Ltd produces and supplies ball bearings.We have professional technical manpower for the mixing of polymer raw materials for the insulation coating of bearings, production of products, and quality control. We will grow together with customers with accurate quality, fast delivery and competitive prices.

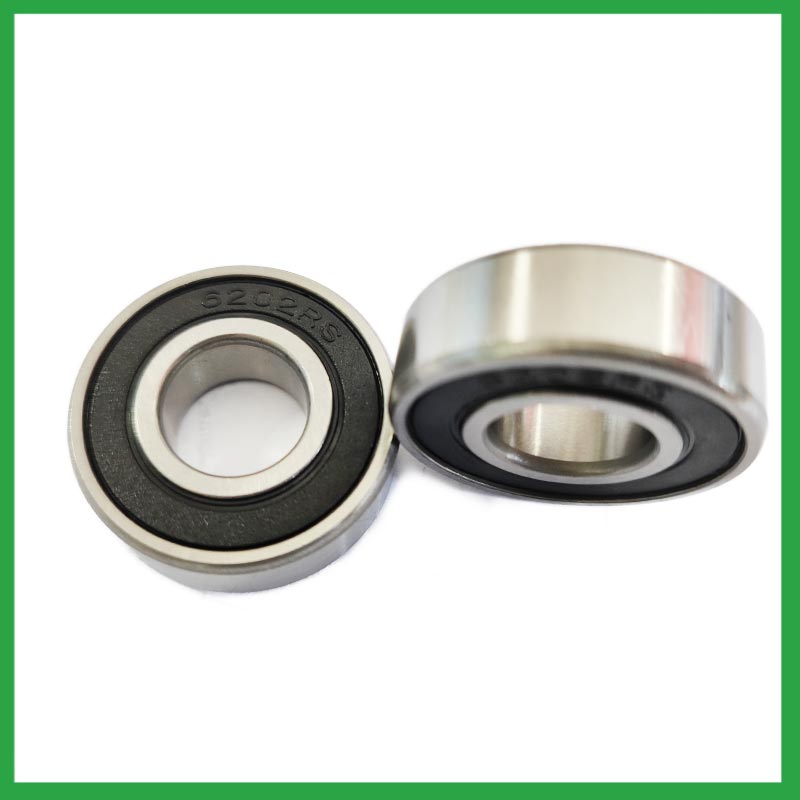

38-7820 - bearing-ball are a commonly used mechanical component that can play an extremely important role in most rotating equipment. It is composed of inner and outer spheres, cages, steel balls, and other components. By rolling the steel balls between the inner and outer spheres, it achieves support and load transfer between the shaft and the shaft seat. Ball bearings have the characteristics of simple structure, light weight, and strong load-bearing capacity, and are widely used in fields such as automobiles, motorcycles, electric tools, and household appliances.

| # | 38-7820 - bearing-ball Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray, white, gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

38-7820 - bearing-ball--A Guide to Frequently Asked Questions

1.Are there ceramic 38-7820 - bearing-ball designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic 38-7820 - bearing-ball are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

2.Are there ball bearings designed for use in critical medical equipment?

Precision bearings are among critical components in medical devices that are vital to ensuring patient safety. Correct choice of suitable ball and ring materials and the right product design can ensure high-precision bearings — and medical devices — have a long service life. Precision bearings are used in a wide variety of medical devices including surgical power tools, ventilators and heart pumps — and patient safety depends on them all. Whatever the device, there is an onus on medical device original equipment manufacturers (OEMs) to ensure that the right type of bearings are chosen, and fit precisely into the application.

3.Are there hybrid ball bearings that combine steel rings with ceramic balls to optimize performance in demanding applications?

Hybrid Ceramic Ball Bearings. Ceramic ball bearings (also known as hybrid bearings) are the one component that'll easily optimize the performance of your application. Hybrid bearings have ceramic (silicon nitride, Si3N4) balls and 52100 bearing steel rings.

4.How do cage materials and designs impact ball bearing performance and stability?

As the core component of rotating machinery, the performance and reliability of high-precision bearing directly affect the overall performance and life of the machine and instrument . The increase of the rotational speed will aggravate the collision and friction of the cage, which will lead to the decrease of the rotational stability of the cage. The unstable movement of the cage could in turn lead to more severe collision and wear, thus reducing the life and reliability or even the destruction of the bearing. Therefore, it is very necessary to study the cage stability to guarantee the stable operation of bearings. However, the dynamic characteristics of the cage is very complex. Parameters such as load, rotational speed and lubrication may affect its kinematic and tribological conditions, which leads to the change of its motion behavior.

5.What anti-corrosion coatings or treatments are available for 38-7820 - bearing-ball used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether 38-7820 - bearing-ball are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

6.Are there miniature ball bearings designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

7.How do preload adjustments in ball bearings affect their performance and suitability for high-precision tasks?

Benefits of Preloading a Bearing Optimizes the ball spin to roll ratio. Increases the rigidity of an application. Protects from excessive ball skidding. Decreases application vibration and sliding friction. High running accuracy (even if load conditions keep changing) Increases bearing load capacity.

8.Are there ongoing research and development efforts aimed at improving ball bearing materials, designs, and lubrication techniques?

A custom bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

9.How do cage designs affect ball bearing speed and acceleration capabilities in high-speed machinery?

In high-speed ball bearings, external load has a great effect on cage stability and sliding ratio, especially for the bearings at work in the starting process. The cage stability is worse in the beginning of the bearing starting process. The axial load greatly influences cage dynamic performance in the bearing starting process. In addition, while ball bearings worked under steady conditions, axial load and radial load both have a great influence on cage dynamic performance. The effects of axial load on cage dynamic performance during the bearing starting process are opposite from the effects under steady conditions.

10.How do different ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove ball bearings: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

11.Can ball bearings be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

12.What maintenance practices are recommended to extend the lifespan of ball bearings and prevent premature failure?

Proper handling and installation of bearings is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.