2023-12-14

Ningbo Haishunide International Co., Ltd. produces products including commutator, ball bearing, shaft, carbon brush, insulation paper, thermal protector, magnet, fan, motor cover and lamination. Apart from these products, we also provide the service for the motor manufacturing technical consultant, project support and turn-key project.

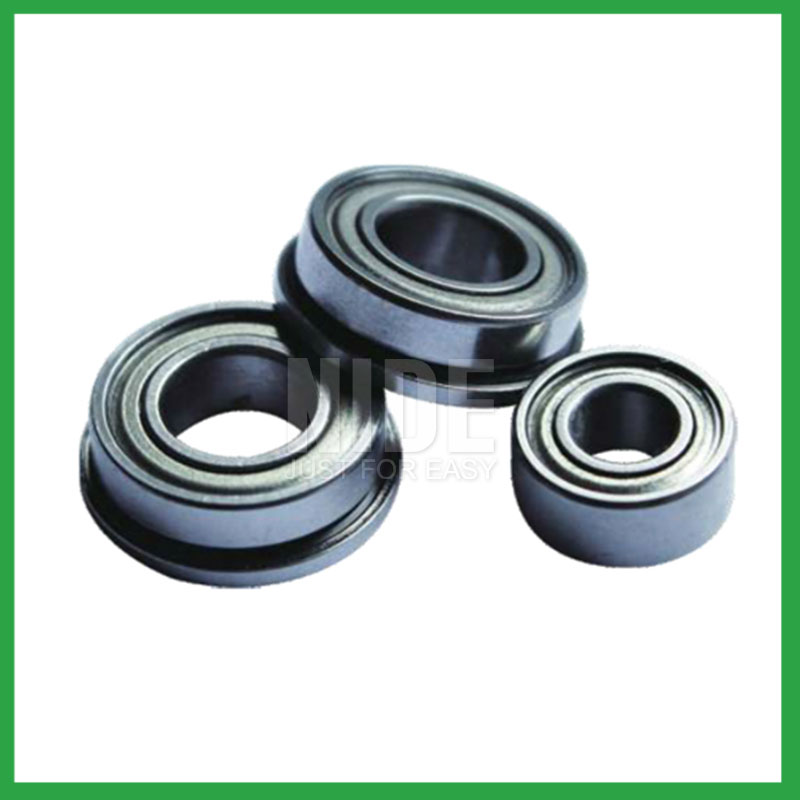

nh ball bearing, which play an important role in the engineering field, are an important type of rolling bearing characterized by long service life, strong load capacity, and good sealing performance. In addition to traditional single row ball bearings, there are also various types of double row, four row, and cross roller ball bearings that can meet various engineering needs. At present, with the development of technology, ball bearings are constantly innovating and improving to adapt to more and more complex mechanical equipment applications.

As a high-precision rotating equipment, nh ball bearing play an important role in various mechanical manufacturing fields, consisting of precision manufactured components such as inner spherical surfaces, outer spherical surfaces, cages, steel balls, etc. It achieves support and load transfer between the shaft and the shaft seat by rolling the steel ball between the inner and outer spherical surfaces. Ball bearings have advantages such as strong load capacity, high speed, and long service life, and are widely used in important fields such as aerospace, ships, and trains.

nh ball bearing, which play an important role in the engineering field, are an important type of rolling bearing characterized by long service life, strong load capacity, and good sealing performance. In addition to traditional single row ball bearings, there are also various types of double row, four row, and cross roller ball bearings that can meet various engineering needs. At present, with the development of technology, ball bearings are constantly innovating and improving to adapt to more and more complex mechanical equipment applications.

| # | nh ball bearing Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray, white, gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

nh ball bearing--A Guide to Frequently Asked Questions

1.What are the considerations for choosing between open, shielded, or sealed nh ball bearing in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded nh ball bearing can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

2.Can ball bearings be used in both vertical and horizontal orientations?

Sleeve Bearings: Sleeve bearings, also known as plain bearings, employ a simple yet effective mechanism. A cylindrical sleeve separates the rotating shaft from the stationary portion of the bearing, reducing friction and enabling smooth rotation. Sleeve bearings are characterized by their quiet operation, cost-effectiveness, and suitability for horizontal mounting orientations. Ball Bearings: Ball bearings introduce small metal balls between the moving parts, providing enhanced durability and reduced friction. This design allows for smoother and more efficient rotation, making ball bearings well-suited for high-performance applications and vertical installations.

3.Can nh ball bearing handle shock loads and high-impact conditions in heavy machinery?

As a general rule, nh ball bearing are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.

4.What is the typical noise level associated with ball bearings, and how are noise-reduction techniques applied?

To measure in accurate way the bearing noise under rotation during their manufacturing process is a key activity particularly in the production of medium, small and ultra-small deep groove ball bearings. This capability in bearings noise analysis has become the real distinguishing element between a standard bearings noise equipment and a superior class one. The various types of vibration and sound in rolling bearings can be grouped in four main categories: structural, manufacturing, handling and other. The structural vibration consists mostly of race, click, squeal and cage noise: it can be continuous or intermittent depending on specific cases. The manufacturing vibration is instead related to the waviness noise generated by the geometrical imperfections of inner and outer ring and of rolling elements, being always continuous in nature. The so-called handling vibration is normally associated with flaw and contamination and is generating – in most of the cases – irregular noise. Then there are other types of vibrabition that include noise generated by sealing and lubricant (irregular) or by runout (continuous).

5.What is the significance of nh ball bearing lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

6.What is the load distribution within a ball bearing, and how does it vary between different bearing configurations?

The load distribution between the rolling elements and raceway is crucial in performance evaluation of rolling element bearings. Determine the load distribution by measuring the strain response at the bearing surface with a notched housing. Finite element analysis shows that the introduction of notches does not affect the load distribution. An experimental system was developed to investigate the load distribution in a cylindrical roller bearing. The experimental static load distribution agrees well with the theoretical calculation. The dynamic load at specific position of load zone reflects the manufacture difference among rollers and dynamic balance of distributing loads.

7.What anti-corrosion coatings or treatments are available for nh ball bearing used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether nh ball bearing are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

8.What are the nh ball bearing product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

9.Are there self-aligning nh ball bearing that accommodate misalignment and shaft deflection in rotating equipment?

These nh ball bearing are particularly suitable for applications where misalignment can arise from errors in mounting or shaft deflection. A variety of designs are available with cylindrical and taper bores, with seals and adapter sleeves and extended inner rings.

10.Are there ball bearings designed for use in critical medical equipment?

Precision bearings are among critical components in medical devices that are vital to ensuring patient safety. Correct choice of suitable ball and ring materials and the right product design can ensure high-precision bearings — and medical devices — have a long service life. Precision bearings are used in a wide variety of medical devices including surgical power tools, ventilators and heart pumps — and patient safety depends on them all. Whatever the device, there is an onus on medical device original equipment manufacturers (OEMs) to ensure that the right type of bearings are chosen, and fit precisely into the application.

11.How do preloaded ball bearings enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

12.Can nh ball bearing be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, nh ball bearing can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements. 1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances. 2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments. 3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products. 4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components. 5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

13.What is the role of nh ball bearing in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

When a load is applied to a ball bearing, the nh ball bearing roll freely between the inner and outer rings. This rolling action significantly reduces friction compared to sliding contact, resulting in smoother rotation and reduced wear.