2023-12-19

By ceaselessly improve our quality and, our products win high praise for our favorable price, excellent service and timely delivery. No matter before or after sales, from quality to price, we have the complete and professional management system.

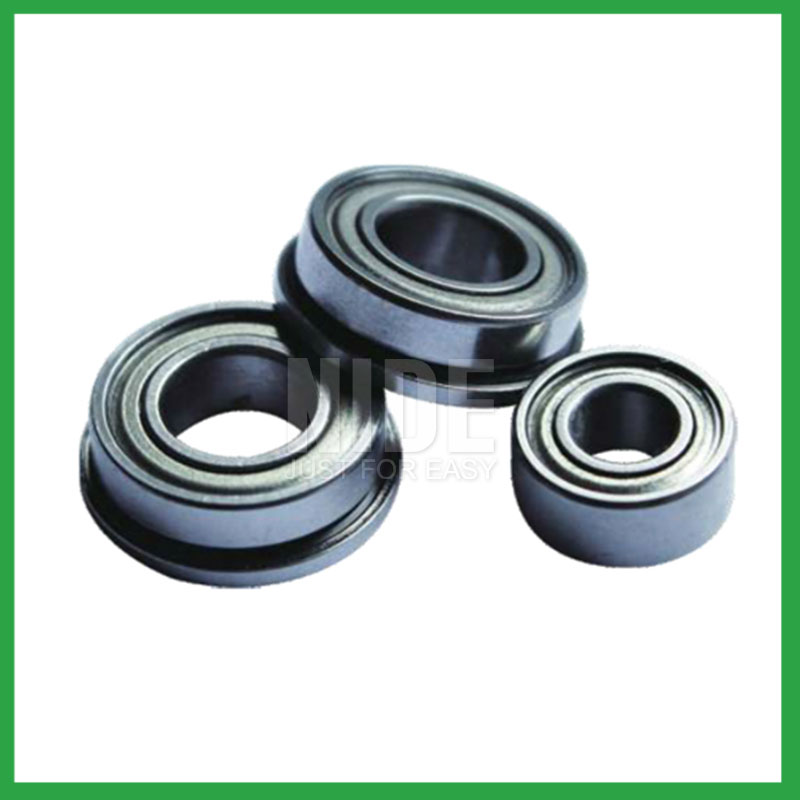

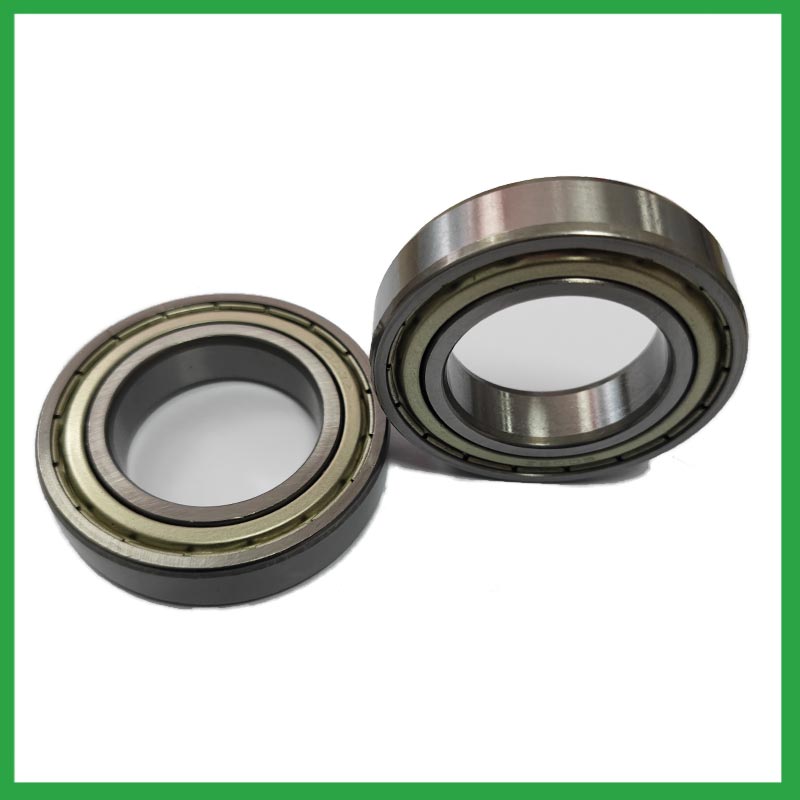

Small ball bearings sizes vary according to their use. The width of the bearing also depends on the application. For example, thin section bearings are used in situations where space is at a premium. The difference between the diameter of the outside and inside races and width is minimized, allowing for compact designs. The materials used in ball bearings depend on their application. The vast majority of ball bearings are made from steel. Other material types include stainless steel bearings for improved corrosion resistance and hybrid ball bearings for which ceramic balls are the moving parts of the bearing between the inner and outer races to reach high rotational speeds.

Small ball bearings are a commonly used mechanical component that can play an extremely important role in most rotating equipment. It is composed of inner and outer spheres, cages, steel balls, and other components. By rolling the steel balls between the inner and outer spheres, it achieves support and load transfer between the shaft and the shaft seat. Ball bearings have the characteristics of simple structure, light weight, and strong load-bearing capacity, and are widely used in fields such as automobiles, motorcycles, electric tools, and household appliances.

As a high-precision rotating equipment, small ball bearings play an important role in various mechanical manufacturing fields, consisting of precision manufactured components such as inner spherical surfaces, outer spherical surfaces, cages, steel balls, etc. It achieves support and load transfer between the shaft and the shaft seat by rolling the steel ball between the inner and outer spherical surfaces. Ball bearings have advantages such as strong load capacity, high speed, and long service life, and are widely used in important fields such as aerospace, ships, and trains.

| # | small ball bearings Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray, white, gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

Small ball bearings--A Guide to Frequently Asked Questions

1.Where can small ball bearings be used?

small ball bearings are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

2.Do small ball bearings come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

3.Can ball bearings be used in both vertical and horizontal orientations?

Sleeve Bearings: Sleeve bearings, also known as plain bearings, employ a simple yet effective mechanism. A cylindrical sleeve separates the rotating shaft from the stationary portion of the bearing, reducing friction and enabling smooth rotation. Sleeve bearings are characterized by their quiet operation, cost-effectiveness, and suitability for horizontal mounting orientations. Ball Bearings: Ball bearings introduce small metal balls between the moving parts, providing enhanced durability and reduced friction. This design allows for smoother and more efficient rotation, making ball bearings well-suited for high-performance applications and vertical installations.

4.What are the small ball bearings product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

5.How do manufacturers ensure the quality and reliability of small ball bearings through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

6.How do ball bearings provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, ball bearings operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

7.What is a ball bearing?

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other. Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races.

8.How do preload adjustments in ball bearings affect their performance and suitability for high-precision tasks?

Benefits of Preloading a Bearing Optimizes the ball spin to roll ratio. Increases the rigidity of an application. Protects from excessive ball skidding. Decreases application vibration and sliding friction. High running accuracy (even if load conditions keep changing) Increases bearing load capacity.

9.How do sealed ball bearings prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the bearing. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.

10.What are the common materials used in ball bearing manufacturing?

Most ball bearings are made of a type of steel known as high carbon chromium steel, often called chrome steel. This is used for reasons of cost and durability. Bearings are also made from other materials such as stainless steel, ceramics and plastic.

11.What is the production capacity of the factory for small ball bearings?

The production capacity of Ningbo Haishu Nide International is:50000000pcs/month

12.Are there ongoing research and development efforts aimed at improving ball bearing materials, designs, and lubrication techniques?

A custom bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

13.Are there miniature ball bearings designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

14.Can ball bearings be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

15.What are the standard sizes and dimensions of ball bearings?

Ball bearing size charts are widely available, and can be used to find the measurements of a specific bearing. Series 6200 and 6300 are the most commonly used, and typically range from 10 x 30 x 9 mm (. 394 x 1.181 x . 354 in) to 150 x 320 x 65 mm (5.906 x 12.598 x 2.559 in).