2023-12-19

Nide team could manufacture ball bearing as per customer’s drawing and samples. If customer only has samples, we could also design drawing for our customer. We also provide customized service.

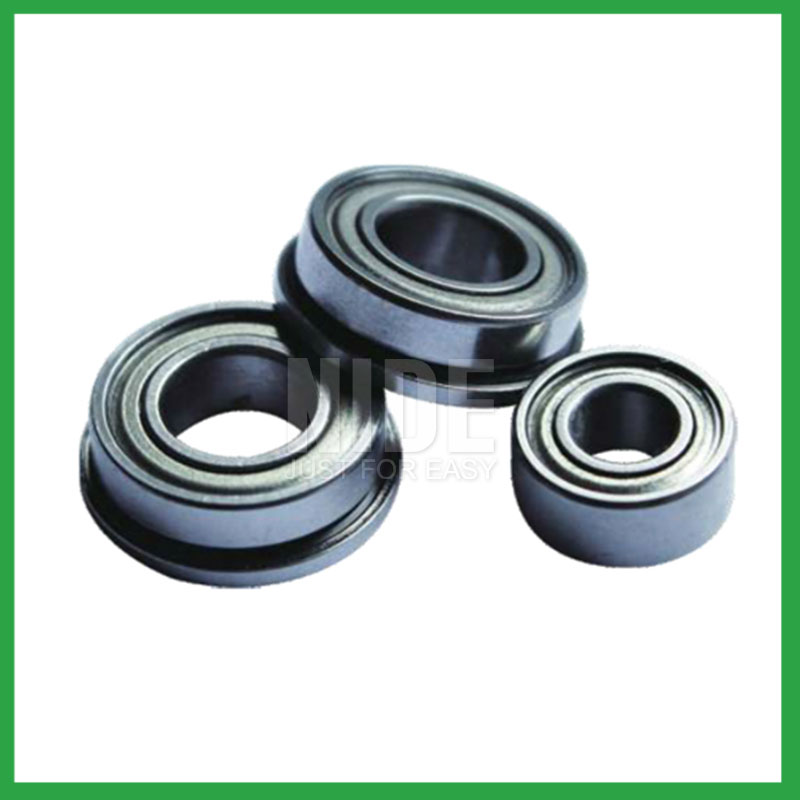

Steel ball bearings, known for their excellent performance and wide applicability, are precision mechanical components. Their inner and outer spheres and cages are machined using high-precision machining techniques, and undergo heat treatment and precision balance correction, enabling the bearings to maintain stable operation during high-speed rotation. In addition to being widely used in the industrial field, ball bearings are also often used in high-precision control equipment such as robots and robotic arms.

Steel ball bearings are a commonly used mechanical component that can play an extremely important role in most rotating equipment. It is composed of inner and outer spheres, cages, steel balls, and other components. By rolling the steel balls between the inner and outer spheres, it achieves support and load transfer between the shaft and the shaft seat. Ball bearings have the characteristics of simple structure, light weight, and strong load-bearing capacity, and are widely used in fields such as automobiles, motorcycles, electric tools, and household appliances.

Steel ball bearings, known for their excellent performance and wide applicability, are precision mechanical components. Their inner and outer spheres and cages are machined using high-precision machining techniques, and undergo heat treatment and precision balance correction, enabling the bearings to maintain stable operation during high-speed rotation. In addition to being widely used in the industrial field, ball bearings are also often used in high-precision control equipment such as robots and robotic arms.

| # | steel ball bearings Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray, white, gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

Steel ball bearings--A Guide to Frequently Asked Questions

1.Can steel ball bearings handle shock loads and high-impact conditions in heavy machinery?

As a general rule, steel ball bearings are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.

2.Do steel ball bearings come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

3.How do ball bearings contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

The balls roll along the raceway, allowing for smooth rotation of the machinery or equipment. Ball bearings are used to support rotating, reduce friction and support radial and axial loads in high-load, high-speed applications where reliability and efficiency are critical.

4.What are the advancements and innovations in steel ball bearings technology that have emerged in recent years?

Significant advancements have been made in bearing steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

5.How do cage designs affect ball bearing speed and acceleration capabilities in high-speed machinery?

In high-speed ball bearings, external load has a great effect on cage stability and sliding ratio, especially for the bearings at work in the starting process. The cage stability is worse in the beginning of the bearing starting process. The axial load greatly influences cage dynamic performance in the bearing starting process. In addition, while ball bearings worked under steady conditions, axial load and radial load both have a great influence on cage dynamic performance. The effects of axial load on cage dynamic performance during the bearing starting process are opposite from the effects under steady conditions.

6.How do manufacturers ensure the quality and reliability of steel ball bearings through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

7.What are the considerations for choosing between open, shielded, or sealed steel ball bearings in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded steel ball bearings can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

8.Are there ball bearings designed for use in critical medical equipment?

Precision bearings are among critical components in medical devices that are vital to ensuring patient safety. Correct choice of suitable ball and ring materials and the right product design can ensure high-precision bearings — and medical devices — have a long service life. Precision bearings are used in a wide variety of medical devices including surgical power tools, ventilators and heart pumps — and patient safety depends on them all. Whatever the device, there is an onus on medical device original equipment manufacturers (OEMs) to ensure that the right type of bearings are chosen, and fit precisely into the application.

9.Are there ceramic steel ball bearings designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic steel ball bearings are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

10.What anti-corrosion coatings or treatments are available for steel ball bearings used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether steel ball bearings are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

Tags: Non Standard Ball Bearings , electric motor ball bearing