2023-11-28

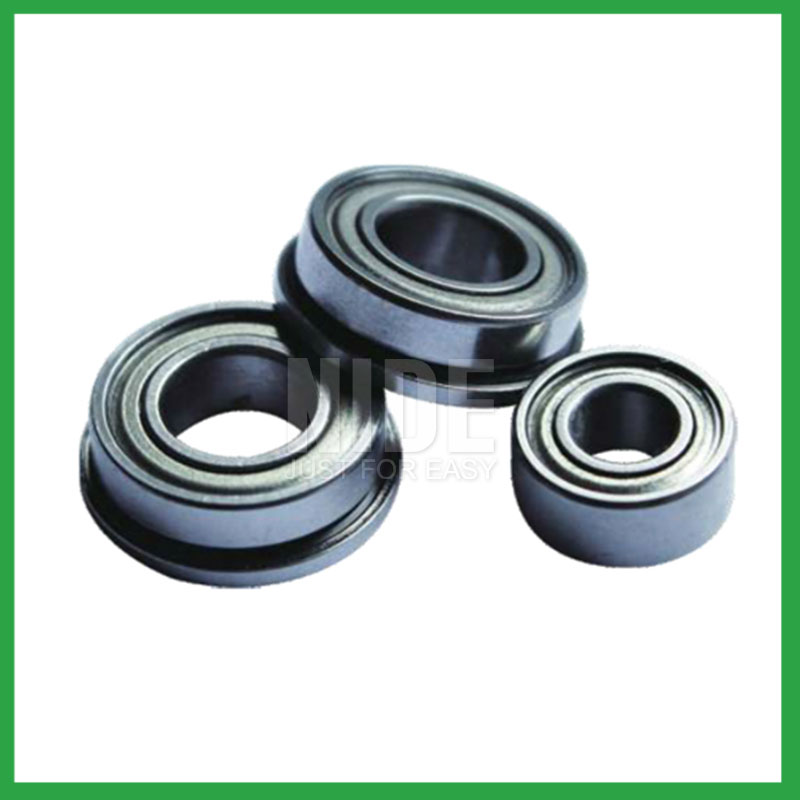

Ball bearing rollers are a commonly used mechanical component that can play an extremely important role in most rotating equipment. It is composed of inner and outer spheres, cages, steel balls, and other components. By rolling the steel balls between the inner and outer spheres, it achieves support and load transfer between the shaft and the shaft seat. Ball bearings have the characteristics of simple structure, light weight, and strong load-bearing capacity, and are widely used in fields such as automobiles, motorcycles, electric tools, and household appliances.

We has professional technology and rich experience in quality control, customs clearance, commodity inspection, cargo transposition, insurance.We has rich stocks and is able to provide long tern stable supply, including rapid and urgent cargo handing . With companies in Europe, America , Japan and Korea, we are an integrated supplier of bearing, marketing all over the world.

ball bearing rollers, known for their excellent performance and wide applicability, are precision mechanical components. Their inner and outer spheres and cages are machined using high-precision machining techniques, and undergo heat treatment and precision balance correction, enabling the bearings to maintain stable operation during high-speed rotation. In addition to being widely used in the industrial field, ball bearings are also often used in high-precision control equipment such as robots and robotic arms.

As a high-precision rotating equipment, ball bearing rollers play an important role in various mechanical manufacturing fields, consisting of precision manufactured components such as inner spherical surfaces, outer spherical surfaces, cages, steel balls, etc. It achieves support and load transfer between the shaft and the shaft seat by rolling the steel ball between the inner and outer spherical surfaces. Ball bearings have advantages such as strong load capacity, high speed, and long service life, and are widely used in important fields such as aerospace, ships, and trains.

| # | ball bearing rollers Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

1.Are there specific ball bearings designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control ball bearings are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses. Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

2.What is the typical noise level associated with ball bearings, and how are noise-reduction techniques applied?

To measure in accurate way the bearing noise under rotation during their manufacturing process is a key activity particularly in the production of medium, small and ultra-small deep groove ball bearings. This capability in bearings noise analysis has become the real distinguishing element between a standard bearings noise equipment and a superior class one. The various types of vibration and sound in rolling bearings can be grouped in four main categories: structural, manufacturing, handling and other. The structural vibration consists mostly of race, click, squeal and cage noise: it can be continuous or intermittent depending on specific cases. The manufacturing vibration is instead related to the waviness noise generated by the geometrical imperfections of inner and outer ring and of rolling elements, being always continuous in nature. The so-called handling vibration is normally associated with flaw and contamination and is generating – in most of the cases – irregular noise. Then there are other types of vibrabition that include noise generated by sealing and lubricant (irregular) or by runout (continuous).

3.Are there ceramic ball bearing rollers designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic ball bearing rollers are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

4.Can ball bearing rollers be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, ball bearing rollers can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements. 1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances. 2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments. 3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products. 4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components. 5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

5.Do ball bearing rollers come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

6.Are there self-aligning ball bearing rollers that accommodate misalignment and shaft deflection in rotating equipment?

These ball bearing rollers are particularly suitable for applications where misalignment can arise from errors in mounting or shaft deflection. A variety of designs are available with cylindrical and taper bores, with seals and adapter sleeves and extended inner rings.

7.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a bearing manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

8.What are the ball bearing rollers product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

9.How do cage designs affect ball bearing speed and acceleration capabilities in high-speed machinery?

In high-speed ball bearings, external load has a great effect on cage stability and sliding ratio, especially for the bearings at work in the starting process. The cage stability is worse in the beginning of the bearing starting process. The axial load greatly influences cage dynamic performance in the bearing starting process. In addition, while ball bearings worked under steady conditions, axial load and radial load both have a great influence on cage dynamic performance. The effects of axial load on cage dynamic performance during the bearing starting process are opposite from the effects under steady conditions.

10.Are there ball bearings designed for extreme temperature environments, such as cryogenic or furnace applications?

High temperature bearings use specialized lubricants to stand up to high temperatures. Grease-packed bearings are pre-filled with fluorine grease for high temperatures, while YS and SJ bearings use molybdenum disulfide (MoS2) solid lubricant to withstand temperatures up to 350°C and 400°C respectively.

11.How do preload adjustments in ball bearings affect their performance and suitability for high-precision tasks?

Benefits of Preloading a Bearing Optimizes the ball spin to roll ratio. Increases the rigidity of an application. Protects from excessive ball skidding. Decreases application vibration and sliding friction. High running accuracy (even if load conditions keep changing) Increases bearing load capacity.

12.Can ball bearings be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

13.What are the advancements and innovations in ball bearing rollers technology that have emerged in recent years?

Significant advancements have been made in bearing steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

Tags: Ball bearing