2023-11-30

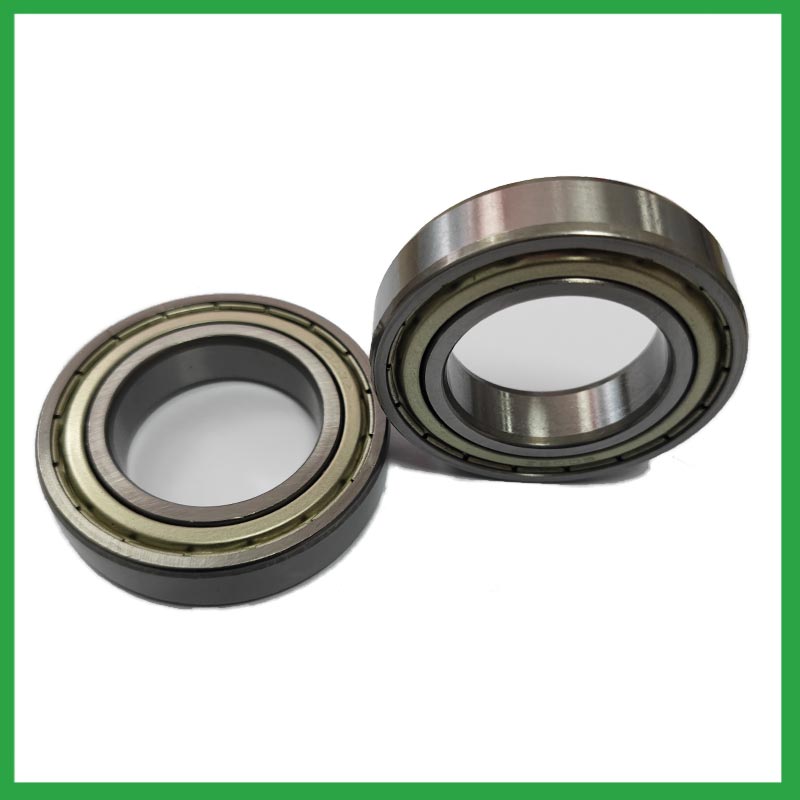

Ningbo Haishunide International Co., Ltd produces and supplies ball bearings.We have professional technical manpower for the mixing of polymer raw materials for the insulation coating of bearings, production of products, and quality control. We will grow together with customers with accurate quality, fast delivery and competitive prices.

The most common ball bearing steel, with one row of balls, is usually classified as a radial ball bearing (i.e., one designed to carry loads perpendicular to the axis of rotation), but its capacity for carrying an axial, or thrust, load (i.e., a load parallel to the axis of rotation) may exceed its radial capacity. The angular-contact bearing has one side of the outer-race groove cut away to allow the insertion of more balls, which enables the bearing to carry large axial loads in one direction only. Such bearings are usually used in pairs so that high axial loads can be carried in both directions. The clearances in a single-row ball bearing are so small that no appreciable misalignment of a shaft relative to a housing can be accommodated. One type of self-aligning bearing has two rows of balls and a spherical inner surface on the outer race. For pure thrust loads there are ball thrust bearings that consist of two grooved plates with balls between. The outstanding advantage of a ball bearing over a sliding bearing is its low starting friction. At speeds high enough to develop a load-carrying oil film, however, the friction in a sliding bearing may be less than in a ball bearing.

As a high-precision rotating equipment, ball bearing steel play an important role in various mechanical manufacturing fields, consisting of precision manufactured components such as inner spherical surfaces, outer spherical surfaces, cages, steel balls, etc. It achieves support and load transfer between the shaft and the shaft seat by rolling the steel ball between the inner and outer spherical surfaces. Ball bearings have advantages such as strong load capacity, high speed, and long service life, and are widely used in important fields such as aerospace, ships, and trains.

ball bearing steel, which play an important role in the engineering field, are an important type of rolling bearing characterized by long service life, strong load capacity, and good sealing performance. In addition to traditional single row ball bearings, there are also various types of double row, four row, and cross roller ball bearings that can meet various engineering needs. At present, with the development of technology, ball bearings are constantly innovating and improving to adapt to more and more complex mechanical equipment applications.

| # | ball bearing steel Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray, white, gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

ball bearing steel--A Guide to Frequently Asked Questions

1.What is the typical noise level associated with ball bearings, and how are noise-reduction techniques applied?

To measure in accurate way the bearing noise under rotation during their manufacturing process is a key activity particularly in the production of medium, small and ultra-small deep groove ball bearings. This capability in bearings noise analysis has become the real distinguishing element between a standard bearings noise equipment and a superior class one. The various types of vibration and sound in rolling bearings can be grouped in four main categories: structural, manufacturing, handling and other. The structural vibration consists mostly of race, click, squeal and cage noise: it can be continuous or intermittent depending on specific cases. The manufacturing vibration is instead related to the waviness noise generated by the geometrical imperfections of inner and outer ring and of rolling elements, being always continuous in nature. The so-called handling vibration is normally associated with flaw and contamination and is generating – in most of the cases – irregular noise. Then there are other types of vibrabition that include noise generated by sealing and lubricant (irregular) or by runout (continuous).

2.What is a ball bearing?

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other. Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races.

3.Are there ball bearings designed for use in critical medical equipment?

Precision bearings are among critical components in medical devices that are vital to ensuring patient safety. Correct choice of suitable ball and ring materials and the right product design can ensure high-precision bearings — and medical devices — have a long service life. Precision bearings are used in a wide variety of medical devices including surgical power tools, ventilators and heart pumps — and patient safety depends on them all. Whatever the device, there is an onus on medical device original equipment manufacturers (OEMs) to ensure that the right type of bearings are chosen, and fit precisely into the application.

4.How do cage materials and designs impact ball bearing performance and stability?

As the core component of rotating machinery, the performance and reliability of high-precision bearing directly affect the overall performance and life of the machine and instrument . The increase of the rotational speed will aggravate the collision and friction of the cage, which will lead to the decrease of the rotational stability of the cage. The unstable movement of the cage could in turn lead to more severe collision and wear, thus reducing the life and reliability or even the destruction of the bearing. Therefore, it is very necessary to study the cage stability to guarantee the stable operation of bearings. However, the dynamic characteristics of the cage is very complex. Parameters such as load, rotational speed and lubrication may affect its kinematic and tribological conditions, which leads to the change of its motion behavior.

5.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a bearing manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

6.Can ball bearings be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

7.What is the role of ball bearings in reducing friction and energy loss in rotating machinery?

Ball bearings reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

8.Are there miniature ball bearings designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

9.How do preloaded ball bearings enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

10.Can ball bearing steel be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, ball bearing steel can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements. 1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances. 2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments. 3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products. 4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components. 5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

11.How do manufacturers ensure the quality and reliability of ball bearing steel through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

12.Do ball bearing steel come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

13.Are there hybrid ball bearings that combine steel rings with ceramic balls to optimize performance in demanding applications?

Hybrid Ceramic Ball Bearings. Ceramic ball bearings (also known as hybrid bearings) are the one component that'll easily optimize the performance of your application. Hybrid bearings have ceramic (silicon nitride, Si3N4) balls and 52100 bearing steel rings.

14.Can ball bearing steel operate in high-speed applications, and what design features make them suitable for such conditions?

They have very low rolling friction and are optimized for low noise and low vibration. This makes them ideal for high-speed applications. ball bearing steel are comparatively easy to install and require minimal maintenance.

Tags: Ball Bearing