PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Electrical 17AM thermal protector water pump motor 150 degrees temperature switch

Introduction to 17AM Thermal Protector

The 17AM thermal protector switch is a thermal protection element that uses a special bimetallic reed, a large-capacity contact, a conductive metal shell and a bottom plate to form a control loop. It has the advantages of small size, fast temperature sensing, reliable performance, etc. It can be fully automated in large quantities and is widely used in the field of thermal protection.

The working principle of 17AM thermal protector

When working, the bimetal reed presses the movable contact on the static contact tightly due to the special curved surface, the contact is closed, and the circuit is turned on. When the electrical appliance generates heat due to a fault, and the temperature rises to the rated operating temperature of the thermal protector, the bimetallic element is heated to generate internal stress and quickly act to reverse the arc, driving the moving contact to instantly jump away from the static contact, causing the contact to break Switch on and cut off the power supply to protect against overheating. When the temperature of the protected electrical appliance drops to the product's rated reset temperature value, the bimetallic element returns to the initial state and the movable contact is closed, and the electrical appliance resumes work.

17AM thermal protector feature

The temperature sensing element is made of bimetallic sheet;

Widely used and cost-effective;

No electric heating effect, life is up to 10,000 times,

Fully sealed assembly, waterproof and moisture-proof

It has the dual performance of sensing temperature and current to move

Padded stainless steel housing, suitable for most dipping processes

Wires of various specifications and lengths can be riveted according to customer needs

17AM Thermal Protector Technical Parameters Technical Parameters

| Product name | Electrical 17AM thermal protector motor component part |

| Model | 17AM |

| Custom processing: | Yes |

| Type | Temperature switch |

| Use | Household appliances, electric motor |

| Size | Small , can be customized |

| Shape | SMD |

| Fusing speed | F/fast |

| Function | Automatic reset |

| Voltage characteristics | Safety voltage |

| Electrical Specification |

AC 250V/5A AC 125V/8A DC12V/10A DC 24V/8A |

| Maximum voltage | 250 (V) |

| Contact form: | normally open/normally closed |

| Action range: | 20-170 degrees (5 degrees apart is a specification) |

| Temperature tolerance: | ±5, ±7 |

| Contact capacity: | 250V/10A 125V/10A |

| Reset temperature: | the action temperature drops to 15-45℃ |

| Contact resistance: | 50mΩ |

| Electric strength: | AC1500V/1min without breakdown |

| Durability: | 10,000 times. |

17AM Thermal Protector Application

Widely used in various types of motors, transformers, lighting appliances, electric heaters, vacuum cleaners, high-pressure cleaners, submersible pumps, high-pressure water pumps, various electric tools, electric heating pads, heaters and other household appliances, electric heating appliances, Instruments, equipment, new energy batteries, etc.

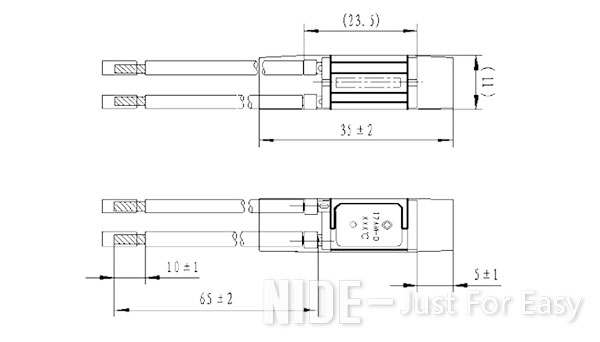

17AM Thermal Protector Picture show

17AM Thermal Protector Instructions

The product shell is made of metal material, and the shell is live when it is energized. It has been equipped with a high-temperature thermally conductive polyester insulation protective sleeve when it leaves the factory. When installing, check whether the thermal protector is placed in the middle of the insulation sleeve, and the insulation sleeve must not be removed. installation.

Do not knock with sharp objects or hard objects to prevent deformation of the shell during installation. Do not install in a humid environment with a humidity greater than 90% or directly immerse in liquid to avoid accidents due to shell deformation, product failure or shell leakage; installation wiring should Pay attention to the good connection of the lead wire to avoid causing the virtual connection to generate heat and affect the normal operation of the thermal protector.

The actual working voltage and working current of the thermal protector should not be greater than its nominal rated voltage and rated current, and it can be used normally if it is less than its nominal rated voltage and rated current.

About Motor component and accessories

NIDE can supply the full range of electric motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email :emarketing@nide-group.com;marketing4@nide-group.com