PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Model:NDPJ-TS-101

Graphite carbon brushes have good reversing performance and long service life. It has good electrical conductivity, thermal conductivity and lubricating properties, and has certain mechanical strength and reversible spark instinct.

Categoryes: Carbon brush

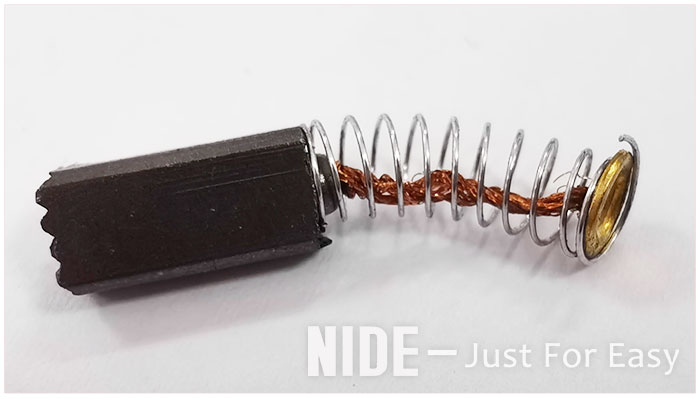

Power Tool Carbon Brush Replacement 5x8x16mm

Graphite carbon brushes are suitable for electric tools, electric hammers, angle grinders, electric drills, etc., with good reversing performance and long service life. It has good electrical conductivity, thermal conductivity and lubricating properties, and has certain mechanical strength and reversible spark instinct.

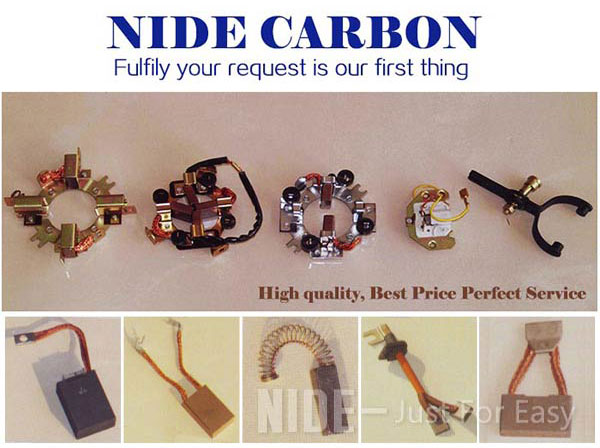

Carbon brush application

Graphite carbon brushes are widely used in electric motors. Applicable to all kinds of electric tool motors, generators, AC and DC generators, synchronous motors, battery DC motors, crane motors, axle machines, various types of welding machines, etc.

Carbon brush material

Graphite carbon brush materials mainly include graphite, fat-impregnated graphite, and metal (copper, silver) graphite.

Carbon brush parameter

| Product Name: | Power Tool Carbon Brush Replacement |

| Material: | Graphite/Copper |

| Carbon brush size: | 5*8*16mm or customized |

| Colour: | Black |

| Use for: | Power Tool, Electric Hammer, Electric Drill, Angle Grinder, etc |

| Packing: | box + carton |

| MOQ: | 10000 |

| Tips: | Since the main component of graphite carbon brush is carbon, it is easy to wear and tear, so it should be regularly maintained and replaced, and the carbon deposit should be cleaned. |

Carbon brush picture

Working principle of graphite carbon brush:

1. The external current (excitation current) is applied to the rotating rotor (input current) through the carbon brush.

2. Introduce the static charge on the large shaft to the ground (grounded carbon brush) through the carbon brush (output current).

3. Lead the large shaft (ground) to the protective device for rotor ground protection and measure the positive and negative voltage of the rotor to ground.

4. Change the direction of the current (in the commutator motor, the brush also plays the role of commutation).

Almost all motors use carbon brushes, which are an important part of the motor. The function of graphite carbon brush is mainly to conduct electricity while rubbing against metal; it is not the same as metal-to-metal friction; when metal-to-metal friction is conductive; the friction force may increase; at the same time, the place where the handover may be sintered together; and Carbon brushes will not; because carbon and metal are two different elements; most of its uses are used in motors; there are various shapes; there are square and round, and so on.

If possible, it will better if customer could send us samples.

We can produce a wide range of carbon brush. Our carbon brush is widely suitable for automotive industry, household appliances, hammers, planers and etc. We could customize carbon brush for our customer and directly supply our carbon brushes to more than 50 countries around the world.

About Motor component and accessories

NIDE can supply the full range of electric motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com