PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

ND-ZZX-5

This automatic motor armature produciton assembly line is used for the manufacturing production of motor rotors (commutators can be hook or groove).

I. The armature rotor production line introduction:

This automatic produciton assembly line is used for the manufacturing production of motor rotors (commutators can be hook or groove).

The automatic motor armature manufactuing line is transmitted by the belt conveyor line, and the front and rear machines can be connected according to a predetermined communication protocol to realize intelligent automatic production, and the workpiece transfer, loading and unloading, detection, and production process transfer can be completed without manual intervention.

The motor rotor production assembly line consists of the main operating table (including the upper and lower feed ports), the rotor shaft pressing machine, the rotor commutator pressing machine , the automatic rotor insulation paper insertion, the double flyers armatur rotor coil winding machine, and the fully automatic rotor commutator spot welder, the automatic rotor slot wedge insertion machine, the armature rotor commutator turning machine, the armature rotor deburring machine, the fully automatic rotor integrated testing machine.

These machines form an automatic rotor production line through belt conveyors.

The workpiece is placed in the production line from the console.

The entire production line will complete the corresponding process according to the relevant process.

Finally, it will be recycled back to the lowering port to remove the completed workpiece.

Each process equipment has functions such as separate setting, display, operation, sound and light alarm.

II. Performance and characteristics

1. This automatic rotor manufacturing production line includes armature shaft presser, armature rotor commutator press, rotor insulation paper automatic inserter, double fly fork armature rotor winder, fully automatic rotor commutator spot welder, automatic armature rotor slot wedge inserter , rotor commutator finishing turning machine, rotor commutator deburring machine, and fully automatic armature rotor testing machine.

2. The complete rotor manufacturing line equipment can be automatically connected or operated independently.

3. Advanced and sophisticated host manufacturing technology combined with a powerful belt conveyor system for a variety of different planar configurations.

4. It has the advantages of simplicity, flexibility, high efficiency and reliability, which can greatly save manpower, reduce labor intensity and effectively improve production and quality.

5. High-strength all-aluminum frame structure, simple and elegant appearance.

6. The main operation console can perform centralized display monitoring and inquiry on the entire production system, and can read and write the process status of the product by manual input instructions, which can change the process of processing the product, and the operation is more humanized.

7. Compared with the pneumatic conveying line, the transmission efficiency is higher, the noise is smaller, and the workpiece is not damaged during transportation; the belt conveying structure combined with the intelligent identification system realizes flexibility from hardware and software, and makes the wiring more flexible and diverse.

8. The whole rotor manufacturing line adopts automatic identification control system. Each process can automatically read, write and identify the machining status of the workpiece, so that the line body can better adapt to complex and diverse production process requirements.

9. Customers can configure different models into a highly efficient and practical automatic production line according to the actual conditions such as product type, technical indicators and production requirements.

III.The main equipment parameters

We can customize the machine according to customer needs, please contact us if you need it.

a. Auto armature rotor commutator pressing machine parameters

|

Product name |

Motor armature commutator pressing machine |

|

Armature O.D: |

20-60mm |

|

Shaft O.D: |

3-15mm |

|

Shaft length: |

32-250mm |

|

Armature slot number: |

8-24 slots |

|

Commutator O.D: |

8-40mm |

|

Speed amplitude modulation: |

0-670Hz |

|

Air source: |

6-6Kg/cm2 |

|

Total power: |

1.0KW |

|

Power source: |

AC220V,50/60Hz |

|

Weight: |

About 400Kg |

|

Dimension: |

910*880*1300mm |

b. Double flyer winder armature coil winding machine parameters

|

Product name |

Armature rotor coil winding machine |

|

Wire diameter: |

¢0.25~¢1mm |

|

Armature O.D: |

¢20~¢60 mm |

|

Armature stack length: |

10~60 mm |

|

Slot type: |

straight slot(No more than 36 slots) |

|

Armature slots number: |

Odd, even slot |

|

Counting Range: |

0~99999 |

|

Commutator diameter: |

¢18~¢40 mm |

|

Fly fork speed: |

0~3000 rpm |

|

Indexing speed: |

0~3000 rpm |

|

Action process: |

Single action, automatic |

|

Air pressure : |

4~6 Kg/cm2 ,0.5-0.7MPa |

|

Machine power: |

4KW |

|

Temperature: |

-10~40℃ |

|

Humidity: |

40~90% |

|

Power supply: |

3phase 380V±10% 50/60 Hz |

|

Total weight: |

about 1,180 Kg |

|

Dimension: |

2000(length)×1300(width)×1800(height) mm3 |

|

Production efficiency: |

800-900set/class(calculated based on 12slots 24hooks, 20turns) |

c. Fully auto motor armature commutator spot welding machine parameters

|

Product name |

Armture commutator hotstaking machine |

|

Loading method: (choose any one from the following three methods) |

1.Manually loading/unloading 2.Manually push guide rail to load/unload 3.Cylinder loading/unloading |

|

Indexing method: |

servo indexing |

|

Commutator type: |

hook or riser |

|

Wire diameter: |

φ0.2mm-φ1.0mm |

|

Armature diameter: |

φ20mm-φ60mm |

|

Armature Stack length: |

10mm-60mm |

|

Shaft length: |

50mm-250mm |

|

Commutator diameter: |

φ10mm-φ40mm |

|

Shaft diameter: |

φ3mm-φ17mm |

|

Commutator hook/riser number: |

≥3 |

|

Zero finding method: |

manually place armature, cylinder drive one block for positioning |

|

Pressure control method: |

spring + cylinder + pressure detection |

|

Welding head cooling method: |

water cooling |

|

Parameter setting: |

set on the touch screen and power source , Parameter also can be set |

|

Power source control method: |

close loop feedback, high accuracy , inversion |

|

Compressed air pressure: |

4kg/cm2-6kg/cm2 |

|

Welding source power: |

three phase AC380V±10% 50HZ 40KW |

|

Water cooler power: |

three phase AC380V±10% 50HZ |

|

Machine weight: |

800kg(for reference) |

|

Dimension: |

785(L)x 910(W)x 2100(H)mm 3 (for reference) |

d. armature rotor commutator turning machine parameters

|

|

Name |

Parameter |

Remark |

|

1 |

Armature OD |

Ф20~Ф60 mm |

Can process up to Ф82 mm(Minor changes are needed) |

|

2 |

Armature stack length |

10~100 mm |

|

|

3 |

Shaft length |

50~250 mm |

|

|

4 |

Length of shaft at commutator end |

6~80 mm |

|

|

5 |

Shaft diameter at commutator end |

Ф3~Ф12 mm |

|

|

6 |

Commutator diameter |

Ф12~Ф42 mm |

|

|

8 |

Commutator roundness |

≤0.003mm |

The commutation material is Ag Cu, Surface hardness of shaft≥HRC45 Shaft Roundness at the bearing position≤1.5u Armature balance control |

|

9 |

Commutator bar-bar roundness |

≤0.002mm |

|

|

10 |

surface roughness |

Ra 0.4 ~ Ra 1.0 |

as requirement |

|

11 |

Maximum cutting amount |

Max 0.12mm for the first cutting |

Direction at commutator diameter |

|

12 |

Armature speed regulation range |

Max 3000rpm |

Touch screen setting |

|

13 |

Z direction Feeding speed |

Stepless adjustable |

Touch screen setting |

|

14 |

Z direction cutting return speed |

non-adjustable |

Internal programming |

|

15 |

Z direction cutting length |

4 different turning lengths can be set |

Touch screen setting:Max 30mm |

|

16 |

Z direction stroke |

Max 40mm |

|

|

17 |

X direction cutter feeding speed |

Stepless adjustable |

Touch screen setting |

|

18 |

X direction cutting return speed |

non-ajustable |

Internal programming |

|

19 |

X direction feeding accuracy |

Min 0.002mm |

Touch screen setting |

|

20 |

Cutter compensation volume |

Min 0.002mm |

Manual touch screen setting |

|

21 |

Rotor rotation during turning |

positive |

Observe the rotor rotation along the axis of commutator:CW |

|

22 |

Air pressure |

Pressure 4~6kg/cm2 |

|

|

23 |

V-block material |

Artificial PCD diamonds |

|

|

24 |

Turning tool material |

Artificial PCD diamonds |

|

|

25 |

Turning tool type |

Wide blade |

12 degrees right/ left deviation |

|

26 |

Machine power |

6KW |

Industrial vacuum cleaner power:2.2KW Deburring machine power:0.2KW |

|

27 |

Power |

AC380V 50/60Hz |

Industrial vacuum cleaner:AC380V 50/60Hz Deburring machine:AC220 50/60Hz |

|

28 |

Machine weight |

About 1100Kg |

Does not include vacuum cleaner and deburring machine weight |

|

29 |

Workpiece operation height |

950mm±50 |

The rotor center is high from the ground center |

|

30 |

Production efficiency |

2200-2500pcs/shift |

10-12 sec/pc |

|

31 |

Dimension |

1100mm(length) x 900mm(width)x 1600mm(height)3 |

|

IV.The main equipment picture display

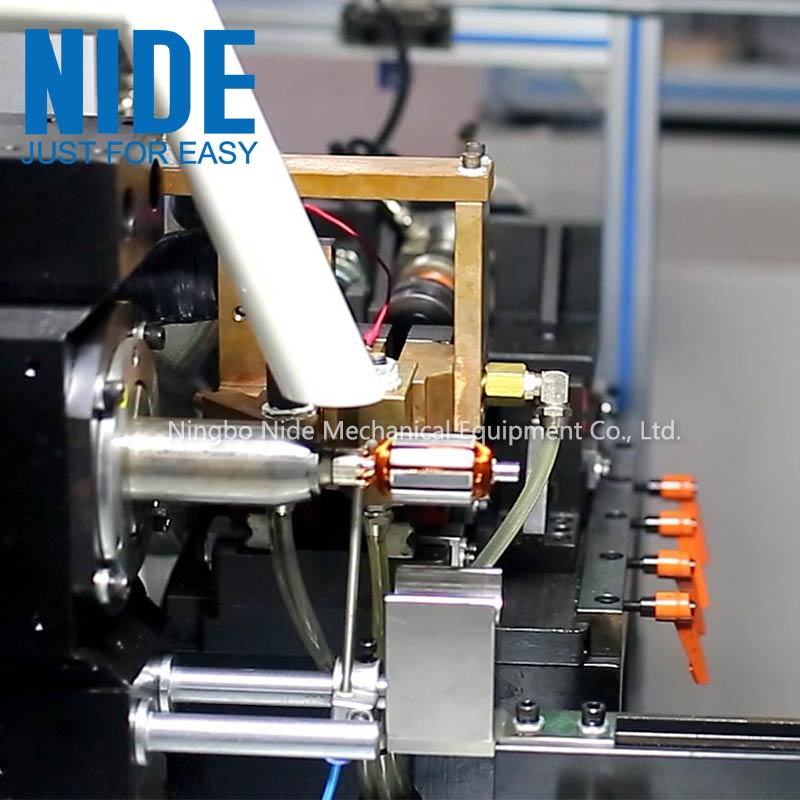

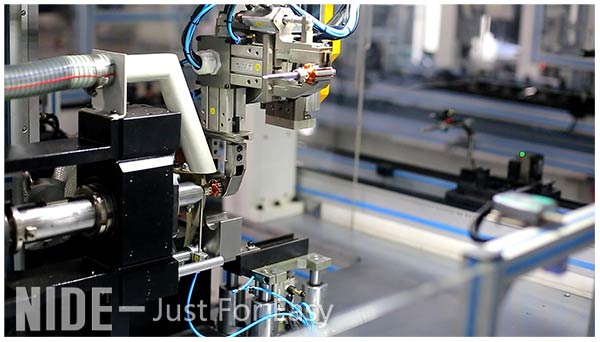

1.The double flyer armature rotor coil winding machine

2. The armature commutator spot welder hot staking machine

3.The armature rotor commutator turning machine

V.The motor armature manufacturing production assembly line youtube video

![]()

| Contact us

Motor Manufacturing Machine Department

Email : emarketing@nide-group.com;marketing4@nide-group.com