PRODUCTS

CONTACT US

Ningbo Haishu Nide International Co., Ltd.

一一

· Contact person:Jack

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No.169, Wohushan Road, Daqi Street, Beilun District, Ningbo, Zhejiang, China

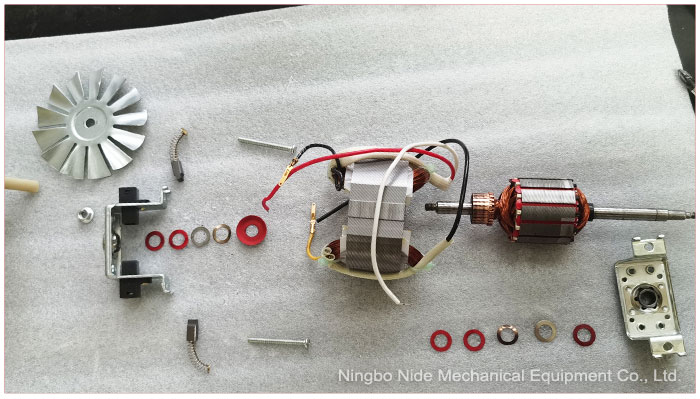

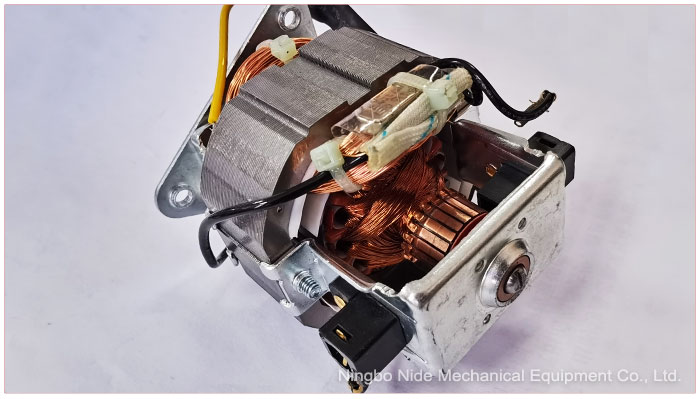

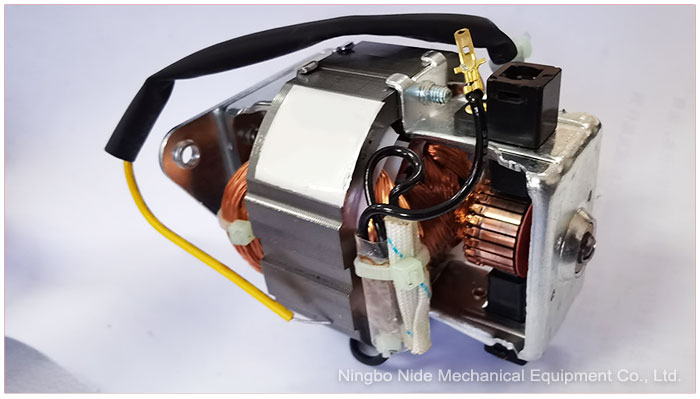

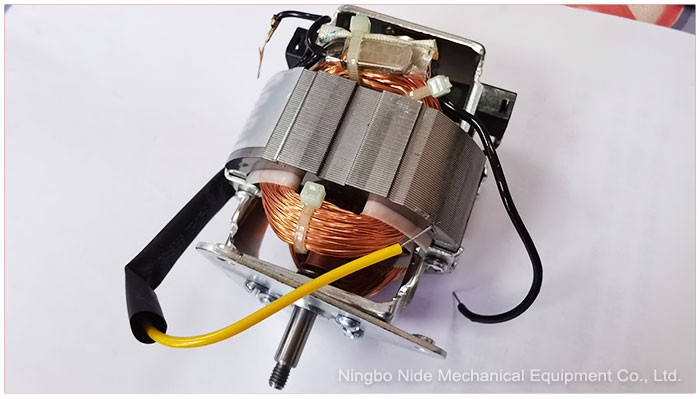

This fully automatic armature winding line is suitable for winding varies type universal electric motor armature and DC motor armatures.

This fully automatic armature winding line is suitable for winding varies type universal electric motor armature and DC motor armatures, such as vacuum cleaner motor, wiper motor, mixer motor, RO pump motor, power tool motor, etc.

It features fast, efficient, accurate winding, easy set-up, user-friendly programming and tooling flexibility.

Main armature making machine technical data

(1)Automatic flyer coil winding machine:

The Automatic Armature Winding machine is designed for winding of various types of hook commutator armature used in home appliances, power tools and automobile industry. As the machine is simple to operate, quick to set to the various armature sizes and high productivity, it is especially suitable for batch winding of motor armatures.

| Input voltage | 220V±10% |

| Rated frequency | 50Hz |

| Motor power | 2.0KW 1500r/min |

| Spindle speed | 0~1500r/min |

| Center height | 160mm(it can be customized.) |

| Max.armature OD | f60mm(it can be customized.) |

| Pre-setting turn number range | 0~32767 |

| Display | true color touch screen |

| Speed adjustment | controlled by touch screen |

| Starting method | manual switch |

| Max. speed | 4000r/min |

| Acceleration time | settable freely(default value is 100-500MS) |

(2)Automatic slot paper inserting machine:

This machine is used for inserting the insulation paper into the armature slot.

| Armature O.D | 20~60mm |

| Shaft length | Max 250mm |

| Shaft O.D | 3~17mm |

| Commutator O.D | 12~40mm |

| Slot number | 8~24 slots |

| Thickness of insulation paper | 0.1mm~0.5mm |

| Length of insulation paper | 10~70mm |

| Type of insulation paper material | DMD, DM, Polyester film |

| Efficiency | 0.5S~0.8S/slot |

| Air source | 4~6Kg/cm2 |

| Rated power | 1.5KW |

| Voltage | AC220V, 50/60Hz |

| Weight | About 400Kg |

| Dimension |

910mm x 880 x 1300mm |

(3)Automatic commutator spot welding machine :

This Commutator hot staking machine is used for commutator hook welding. It is automatically indexing, automatically welding,you only need to load and unload the armature. Welding current can be adjusted according to different wire diameter. Easy operation and adjustment.

| Armature diameter | 15~100mm |

| Commutator diameter | 5~60mm |

| Wire diameter | 0.07~1.8mm |

| Max power | 25KVA |

| Power supply voltage | 220V±10%50Hz |

| Air source pressure |

0.5~0.7MP |

(4)Automatic armature commutator turning machine :

The turning machine is used for armature commutator outer surface turning. Single cutter , can turn more than one time. Positive knife.Three-axis servo control.

| Name | Parameter |

| Armature OD | 20~60 mm |

| Armature stack length | 10~100 mm |

| Shaft length | 50~250 mm |

| Length of shaft at commutator end | 6~80 mm |

| Shaft diameter at commutator end | 3~12 mm |

| Commutator diameter | 12~42 mm |

| Commutator roundness | ≤0.003mm |

| Commutator bar-bar roundness | ≤0.002mm |

| surface roughness | Ra 0.4 ~ Ra 1.0 |

| Maximum cutting amount | Max 0.12mm for the first cutting |

| Armature speed regulation range | Max 3000rpm |

| Z direction Feeding speed | Stepless adjustable |

| Z direction cutting length | 4 different turning lengths can be set |

| Z direction stroke | Max 40mm |

| Rotor rotation during turning | positive |

| V-block material | Artificial PCD diamonds |

| Turning tool type | Wide blade |

| Machine power | 6KW |

| Power | AC380V 50/60Hz |

| Machine weight | About 1100Kg |

| Workpiece operation height | 950mm±50 |

| Production efficiency | 2200-2500pcs/shift |

| Dimension | 1100mmx 900mmx1600mm |

Our fully automatic motor assemble line is suitable for varies type induction motor assembly, BLDC motor assembly, universal electric motor and DC motor assembly, It could automatically assemble the rotor, armature, stator and motor components together . It is used for washing machine motor, fan motor, BLDC motor, DD motor, electric bicycles motor , electric vehicle motor , hub motor, DD BLDC washing machine motor , compressor motor, vacuum cleaner motor, power tool motor, wiper motor, mixer motor, RO pump motor, NEMA motor, DC motor, etc. It features fast, efficient, accurate winding, easy set-up, user-friendly programming and tooling flexibility.

Nide provides turn-key service and technical consultance for motor production technology, it covers varies type motors. We could accomplish tailored and innovative solutions to meet all quality and production requirements, aim at making motor production easier.

![]()

| Contact us

Motor Manufacturing Machine Department

Email : emarketing@nide-group.com;marketing4@nide-group.com