2023-12-19

By ceaselessly improve our quality and, our products win high praise for our favorable price, excellent service and timely delivery. No matter before or after sales, from quality to price, we have the complete and professional management system.

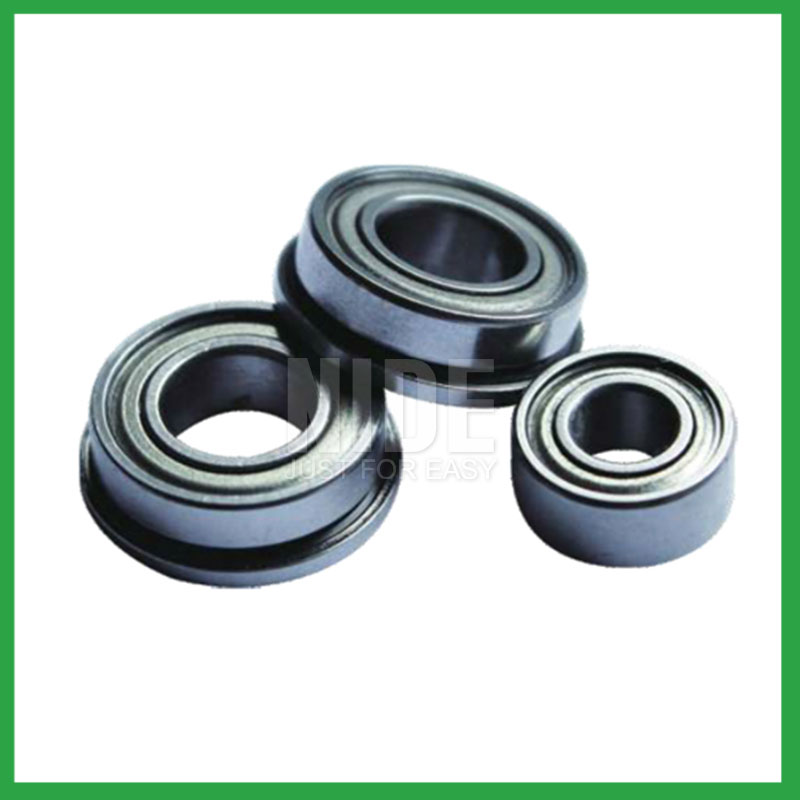

Thrust ball bearing are a commonly used mechanical component that can play an extremely important role in most rotating equipment. It is composed of inner and outer spheres, cages, steel balls, and other components. By rolling the steel balls between the inner and outer spheres, it achieves support and load transfer between the shaft and the shaft seat. Ball bearings have the characteristics of simple structure, light weight, and strong load-bearing capacity, and are widely used in fields such as automobiles, motorcycles, electric tools, and household appliances.

Thrust ball bearing, known for their excellent performance and wide applicability, are precision mechanical components. Their inner and outer spheres and cages are machined using high-precision machining techniques, and undergo heat treatment and precision balance correction, enabling the bearings to maintain stable operation during high-speed rotation. In addition to being widely used in the industrial field, ball bearings are also often used in high-precision control equipment such as robots and robotic arms.

As a high-precision rotating equipment, thrust ball bearing play an important role in various mechanical manufacturing fields, consisting of precision manufactured components such as inner spherical surfaces, outer spherical surfaces, cages, steel balls, etc. It achieves support and load transfer between the shaft and the shaft seat by rolling the steel ball between the inner and outer spherical surfaces. Ball bearings have advantages such as strong load capacity, high speed, and long service life, and are widely used in important fields such as aerospace, ships, and trains.

| # | thrust ball bearing Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray, white, gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

Thrust ball bearing--A Guide to Frequently Asked Questions

1.Can thrust ball bearing be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, thrust ball bearing can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements. 1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances. 2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments. 3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products. 4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components. 5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

2.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a bearing manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

3.Can thrust ball bearing handle shock loads and high-impact conditions in heavy machinery?

As a general rule, thrust ball bearing are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.

4.What is the typical noise level associated with ball bearings, and how are noise-reduction techniques applied?

To measure in accurate way the bearing noise under rotation during their manufacturing process is a key activity particularly in the production of medium, small and ultra-small deep groove ball bearings. This capability in bearings noise analysis has become the real distinguishing element between a standard bearings noise equipment and a superior class one. The various types of vibration and sound in rolling bearings can be grouped in four main categories: structural, manufacturing, handling and other. The structural vibration consists mostly of race, click, squeal and cage noise: it can be continuous or intermittent depending on specific cases. The manufacturing vibration is instead related to the waviness noise generated by the geometrical imperfections of inner and outer ring and of rolling elements, being always continuous in nature. The so-called handling vibration is normally associated with flaw and contamination and is generating – in most of the cases – irregular noise. Then there are other types of vibrabition that include noise generated by sealing and lubricant (irregular) or by runout (continuous).

5.What maintenance practices are recommended to extend the lifespan of ball bearings and prevent premature failure?

Proper handling and installation of bearings is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.

6.Are there specific ball bearings designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control ball bearings are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses. Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

7.What are the after-sales services available for thrust ball bearing?

If you find problems or failures in the assembly or use of the bearings , which needs to consult and other services, please feedback to Nide International in time.

8.How do cage materials and designs impact ball bearing performance and stability?

As the core component of rotating machinery, the performance and reliability of high-precision bearing directly affect the overall performance and life of the machine and instrument . The increase of the rotational speed will aggravate the collision and friction of the cage, which will lead to the decrease of the rotational stability of the cage. The unstable movement of the cage could in turn lead to more severe collision and wear, thus reducing the life and reliability or even the destruction of the bearing. Therefore, it is very necessary to study the cage stability to guarantee the stable operation of bearings. However, the dynamic characteristics of the cage is very complex. Parameters such as load, rotational speed and lubrication may affect its kinematic and tribological conditions, which leads to the change of its motion behavior.

9.What is the production capacity of the factory for thrust ball bearing?

The production capacity of Ningbo Haishu Nide International is:50000000pcs/month

10.How do sealed ball bearings prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the bearing. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.

11.How do ball bearings contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

The balls roll along the raceway, allowing for smooth rotation of the machinery or equipment. Ball bearings are used to support rotating, reduce friction and support radial and axial loads in high-load, high-speed applications where reliability and efficiency are critical.

Tags: Spherical Roller Ball Bearings , ball carbon steel bearing